The reinforcement must be prefabricated with stirrups in place for easier on-site assembly. Reinforcing bars must be produced in accordance with the bar bending schedule and standard rebar arrangement drawings.

Table of Contents

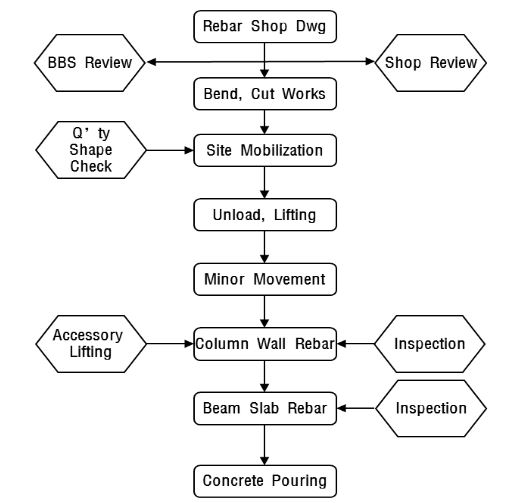

Rebar cutting and bending

- The subcontractor is responsible for preparing the timetable for bar bending in accordance with the consultant’s approved “For Construction” drawings. Prior to the inspection of the rebar, the revised drawing must be reviewed. Control of drawings must be incorporated into the consultant’s document control procedure.

- The tag cords shall be created according to the bar bending schedule order reference; the kind, size, and shape of the rebar shall be identified on the tag label.

- As needed, bundles of rebar will be taken from stock.

- The machine shall cut rebar in accordance with the established bar bending schedule measurement.

- The machine will bend rebar according to the specifications of the supplied bar bending schedule.

- Prefabricated reinforcing bars must be delivered to the installation site.

Rebar Testing Sequence

- The rate of testing is as follows.

- One analysis per test unit for chemical composition.

- The steel manufacturer should have determined the chemical composition (cast analysis) of the metal.

- For bending tests, nominal mass per meter and surface geometry, one specimen per test unit, and nominal diameter are required.

- One test piece per 30 t for tensile tests, with at least three test pieces per test unit and nominal diameter.

- Where bars and coils are created for the production of welded metal products.

- Each 30 t manufactured necessitates one tensile test specimen.

- According to BS4449:2005, test findings shall be reviewed.

Rebar storage and maintenance on site

- The timber flat forms must be created, and the reinforcing bar must be unloaded on the ground at a designated place close to the installation site.

- Before installation, rebar must be temporarily covered and protected with polythene sheets.

- The rebar must be wire-brushed prior to installation and the engineer’s final inspection.

Rebar Installation

- The installation of rebar must be performed using bent rebar in accordance with approved “For Construction” drawings.

- The spacer must be used in accordance with the materials approval.

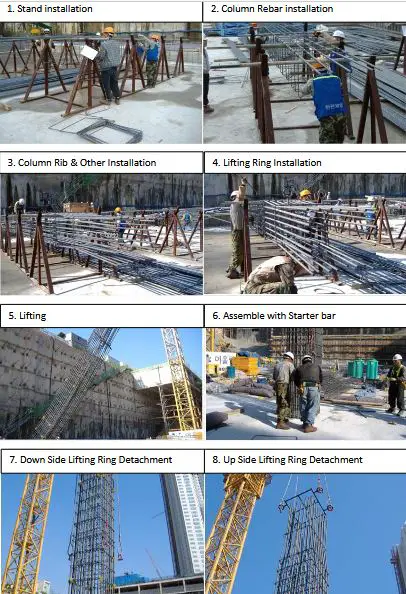

Pre-fabrication of Rebar for Columns

- In the rebar stock files, provide a location for pre-assembly. To install the pre-rebar assembled member, it is necessary to place rebar on the stand.

- To keep things from being out of place, the main rebar and vertical rebar must be arranged according to the dimensions of the drawing.

- Before attaching the lifting ring, the rebar tie must be inspected to confirm that the rebar has been properly placed and secured.

- Place the lifting ring in the four corners of the pre-assembled column’s bottom and top portions.

- Crane-assisted lifting of pre-assembled columns is preferred. A generic lifting plan will be utilized to elevate the prefabricated column.

- After securing the overlapped area, the bottom ring should separate from the member gradually.

- Install the starter bars and ensure the vertically oriented rebar’s alignment, connectivity, and ties.

- After removing the upper ring and prepping the formwork, concrete is poured.

Pre-Fabrication Works

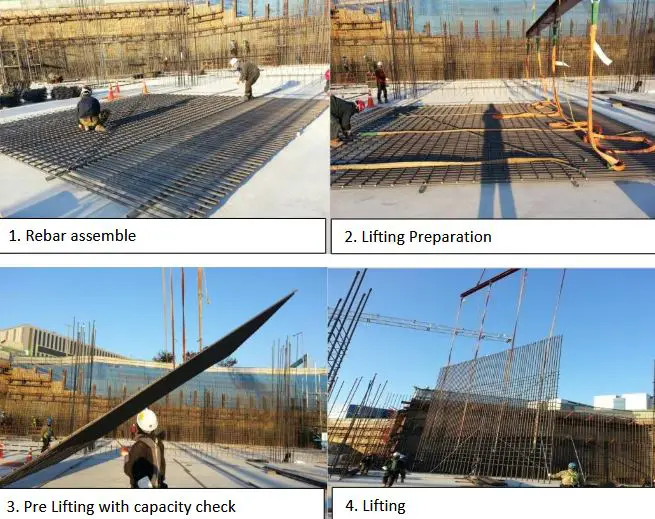

Pre-fabrication of Rebar for Walls

- In the rebar stock piles, establish a pre-assembly area. To install the pre-assembled rebar wall, the rebar wall must be arranged using an angle stand.

- Arrange main rebar and vertical rebar according to drawing dimensions to prevent misalignment for vertical lapping splice using dowels embedded in concrete.

- Determine the position of the prefabricated rebar wall to be installed by establishing the reference line and offset line.

- Provide leveling pads for adjusting the wall’s level prior to assembly.

- Place the lifting ring on the horizontal bar in the upper section of the prefabricated wall. A qualified rigger is needed to install this lifting ring.

- Prefabricated rebar wall by crane with lifting apparatus. A third-party certification of the lifting device is required. The lifting of prefabricated walls will be carried out in accordance with a specialized lifting plan and a single lifting size.

- After securing the overlap zone with a knot, the lifting ring should be slowly removed.

- Attach the overlapping or vertical bar to the dowel bar and ensure the alignment is secure.

- Prior to the placement of concrete, remove the lifting ring and prepare the formwork.