This is the beginning of a series of articles about concrete repair work. In this series, we will discuss how to rectify defects such as cracks, honeycombs, voids, etc. that occur in structural or non-structural concrete elements.

Let’s first take a glance at the different repair work involved with concrete.

Table of Contents

Different Concrete Repair work

- Cracks in reinforced concrete members due to segregation, crazing, excessive drying, etc. as a result of insufficient or delay in curing.

- Cracks in concrete members due to early removal of formwork.

- Honeycombs in concrete due to poor compaction.

- Exposed reinforcement due to improper provision of cover blocks or any cover provision method.

- Improper concreting due to bad arrangement of dense reinforcement.

Now, let’s first talk about cracks and how to monitor them before we begin to learn about crack rectification.

Procedure for Crack Monitoring

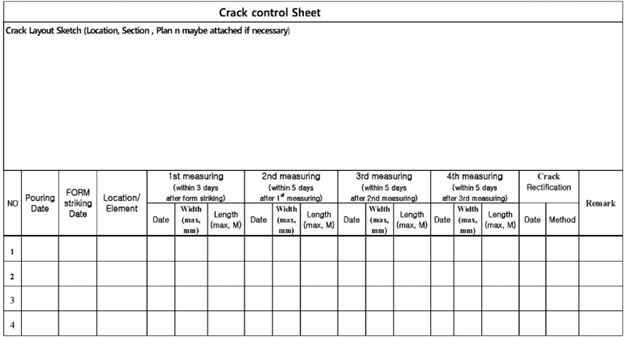

The recommended duration for crack monitoring is generally two weeks after the first finding with a 5-day interval.

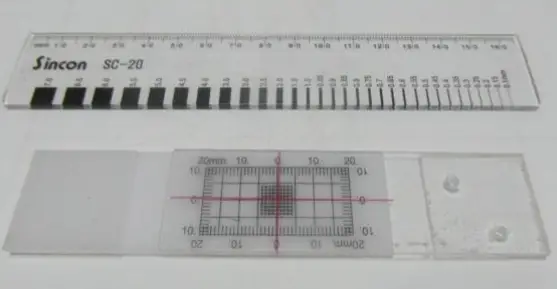

The monitoring tools required for this purpose is the crack gauge (2 types). Most of the time the area around the crack may have to be chipped using a light duty demolition hammer in order to enable a closer visual and easy rectification.

Crack depth has to be measured with a fine wire (and measuring gauge) and noted in the crack control sheet’s “Remarks” column. Prior to doing the rectification, the depth must be confirmed.

Let us now investigate the different types of cracks that could develop in concrete based on the width and depth of the crack.

Crack Types

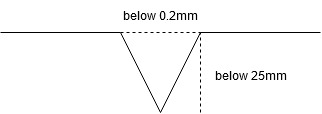

Type 1

Cracks with width below 0.2mm and depth below 25mm are recognized as type 1 cracks. Also called hairline cracks.

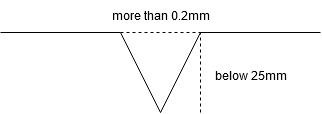

Type 2

Cracks with width more than 0.2mm and depth below 25mm. These are known as Surface cracks.

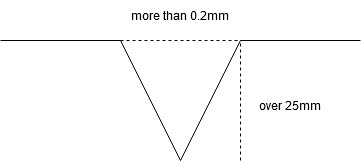

Type 3

Cracks with a width of more than 0.2mm and a depth of over 25mm belong to Type 3 cracks. These cracks are termed “structural cracks.

Recommended Defect Rectifying Materials

| Material | Uses |

| Sikadur®-52 | Injection (Epoxy): Rectification of cracks (width>0.4mm) |

| Sikadur®-31 CF Normal | Epoxy adhesive and repair mortar |

| Sika® Microcrete-2000 | Grouting material: Rectification of cracks, voids & honeycombs (75mm~25mm) Max strength at 28 days: > 65 N/mm2 Max Conc grade for repair: C50/60 |

| Sikatop-armatec-110 | Bonding primer and reinforcement corrosion protection |

| EMACO 157D Primer (Barra Emulsion) | Bonding agent |

| Mapefill GP | Grouting material: Rectification of cracks, voids & honeycombs Max strength at 28 days: > 55 N/mm2 Max Conc grade for repair: C40/50 |

| HA Cut CFL AF & MASTERSEAL 590 | Cracks and voids in watertight structures. |

| Conbextra UHS | High Strength Repair Grout Max strength at 28 days: > 90 N/mm2 Max Conc grade for repair: C70/85 |

| Fosroc Renderoc HS | Grouting material: Rectification of cracks, voids & honeycombs Max strength at 28 days: > 80 N/mm2 Max Conc grade for repair: C50/60 |

| CHRYSO® Cure AC, Antisol®-A, JetCure R | Curing agent |

| Readymixed Concrete with same grade or higher grade | For Voids and honeycombs more than 75mm |

However, before attempting to repair cracks, the following should be taken into consideration:

The reason for the cracking must be determined before attempting to repair it. The amount of movement must be calculated if the crack is dynamic. Repairing a crack is pointless if the structure is still subject to the loads that produced it. Simply put, the structure will crack again at the next weakest place. If the crack is proven to be dynamic, it should be cut or a suitable new joint introduced and sealed with the proper sealant to accommodate the movement.

In the coming articles, we will discuss in detail the methods used for repairing any cracks that show up in concrete as a result of shrinkage, excessive drying, early removal of formwork, and so on.

See this: Concrete Repair Work – Part 2

See this: Concrete Repair Work – Part 3

See this: Concrete Repair Work – Part 4

See this: Concrete Repair Work – Part 5

See this: Concrete Repair Work – Part 6