This article describes the work sequence that a site engineer should follow during concrete placement/concreting.

Table of Contents

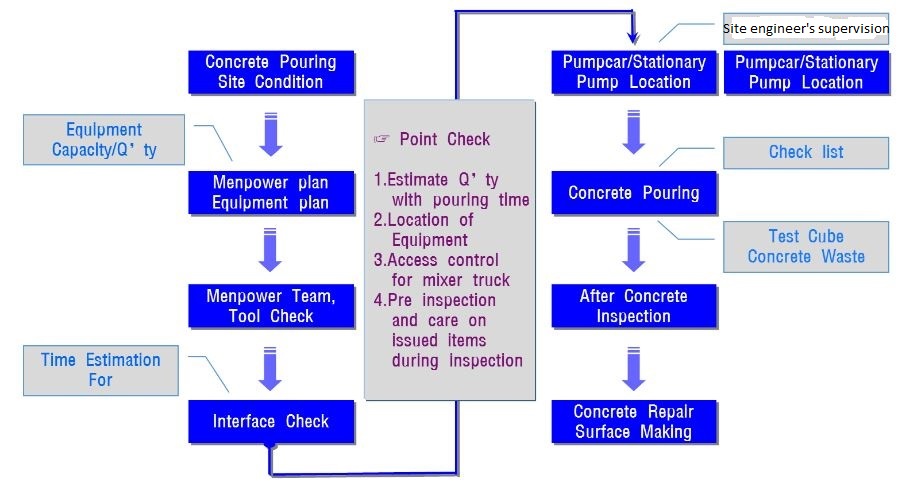

Work Sequence Flow chart for Concrete Work

Prior arrangements for concreting

Cleaning must be carried out to remove all debris such as binding wire, wood, and r/f bits, among other things.

The site engineer will examine the availability of equipment/tools (pokers/vibrators).

Prior to pouring the concrete, the concrete line, CPB, and stationary pump must be installed. The site engineer is responsible for checking and reviewing emergency cases.

If necessary, lighting will be provided. Access must be adequate (clear and safe).

Before seeking a site engineer inspection, the contractor must guarantee that appropriate staff is available for the concreting process.

Prior to concreting, construction joints should be adequately prepped.

The pouring of walls and columns

Concrete must be compacted completely both during and shortly after placement.

To condense the material, mechanical vibrators and shutter vibrators will be employed.

The vibration must be of sufficient duration and intensity to properly compact the concrete but not so long that it causes segregation.

To avoid segregation, the pouring height should not exceed 1.5 m. The tremie pipe will be utilized to keep the group together if they fall more than free fall height.

Each layer must be compacted so that a contraction junction does not form with the prior layer, which did not take initial settlement.

The concrete cover must be maintained in line with the drawing during the casting process.

Pouring of the Slabs

Concrete must be compacted properly both during and shortly after placing.

The material will be compacted using mechanical vibrators.

The vibration should be long enough and intense enough to compact the concrete thoroughly, but not so long that it causes segregation.

The concrete cover must be maintained in line with the drawing during the casting operation.

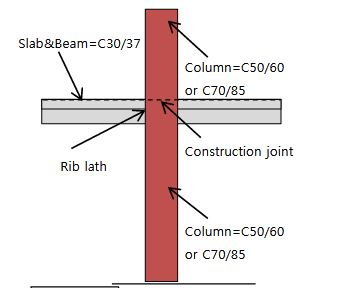

Concreting Vertical and Horizontal Members of Different Concrete Strengths

Rib lath will be used in between vertical and horizontal elements where the concrete strengths differ.

The usage of certified rib lath mesh is required.

Concrete Sampling and testing

Read ALL YOU NEED TO KNOW ABOUT CONCRETE for more information.

Consolidation of concrete

The pouring approach shall be determined during the stage of developing the construction plan for concreting on construction joints and sections while taking the conditions into account. Prior to the contractor putting concrete, the concrete plan must be accepted.

A pre-job meeting will be held at the site to review and confirm each member’s responsibilities. (staff and labor)

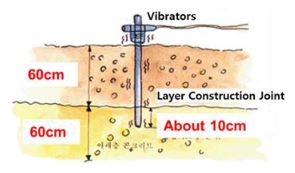

To knit the two layers together, the vibrator should be operated in an up-and-down motion for 5 to 15 seconds.

The vibrator should be operated in a near vertical position when consolidating each layer of concrete, and the vibrating head should be permitted to penetrate under the action of its own weight.

Because of its self-leveling consistency, flowing concrete may appear to be consolidated as it is laid, but it requires vibration to be properly consolidated.

Concrete should not be moved or spread with vibrators.

For every three vibrators in use, one or more spare vibrators in good operating order must be ready for instant use at the point of placement.

Concrete vibration pipes of various diameters will be used depending on the site conditions.

Concreting ramp and slope

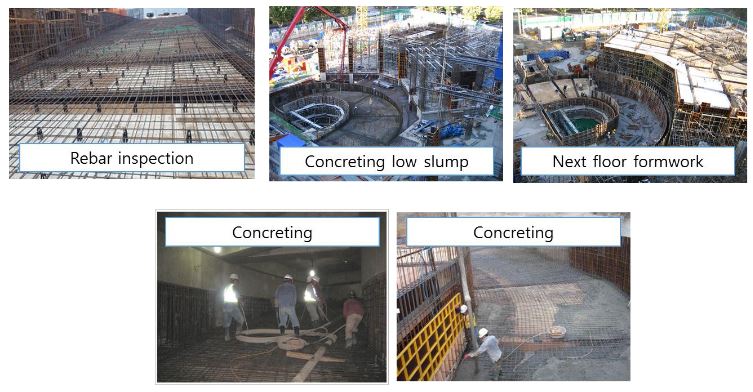

The form work inspection must be performed before pouring concrete.

When the line becomes stagnant, low slump concrete will be prepared, and the equipment will be examined for the emergency plan.

The finish must be in conformity with the authorized drawing and detail.

Water jet operation

After a few hours of concrete finishing, a water jet is applied to the horizontal CJ region.

A retarder will be employed on a horizontal concrete surface in accordance with typical manufacturing performance data. Use a low-pressure sprayer or a soft-bristled brush to apply the substance. Plastic sheeting should be used to protect the applied surface from quick drying and rain.

Remove the sheeting one day after placing the concrete to ensure that the core of the concrete has hardened, and then hose off the treated surface with medium water pressure to wash away the unset cement paste in the surface matrix.

CJ mechanical chipping can be utilized as an alternative approach on CJ after 7 days of curing.

Vertical (Wall/Slab)-Chipping, Horizontal-Retarder+ water jet for construction joint preparation.

Curing

Read ALL YOU NEED TO KNOW ABOUT CONCRETE for more information.