Sealed concrete is a concrete surface treated with either a penetrating sealer or film-forming products like acrylic to enhance its durability and resistance to moisture, stains, and abrasions.

In this comprehensive article on “What is Sealed Concrete?“, we delve into the different types of sealed concrete – from penetrating sealers to film-forming variants – and explore the benefits and potential drawbacks of each. Whether you’re considering sealing your concrete or just curious about the process, we’ll guide you through its advantages, disadvantages, and even help you select the right sealer for your needs, complete with application tips.

Table of Contents

Types of Sealed Concrete

Concrete sealers can be categorized into two main types: Penetrating and Film-forming. Each has its own subtypes and specialty. Let’s explore each category and its properties in detail.

Penetrating Sealers

These sealers penetrate the concrete to form a chemical barrier that shields against moisture, deicing chemicals, and other harmful substances. They’re invisible to the naked eye and leave the surface with a natural look.

Major types of penetrating concrete sealers are Silane, Siloxane, Siliconate, Silicate or Silica, and Fluorinated. These are mainly classified into:

- Densifiers and Hardeners: Typically based on Silicate or Silica chemistries. They penetrate the surface and induce chemical reactions, creating a hard, damage-resistant surface.

- Water Repellents: Derived from Silicone compounds like Silane, Siloxane, Siliconate, or Fluorinated chemistries. They offer excellent water repellency. The Fluorinated ones provide both water and oil repellency.

Noteworthy, some penetrating sealers are solvent-based, while most are water-based, and can vary in VOC level and solid content. Some come in colors or tint packs, providing a transparent or translucent finish.

Film-Forming Sealers

Also known as topical or surface-coating sealers, film-forming sealers coat the entire surface creating a protective layer. Different from penetrating ones, these adhere to the concrete pores and sit on top rather than sinking in.

They offer strong protection from moisture, and spills and are highly durable, requiring easy maintenance and reapplication. There are three main types of film-forming sealers, each with unique properties.

Acrylic Sealers

Ideally suited for general protection against dirt in both indoor and outdoor settings. They form a thin protective layer on the concrete surface and are easy and quick to apply.

While being a cost-effective choice, they may wear out faster due to the thinner layer and require regular recoating.

Both water-based and solvent-based formulations are available, and they come in distinctive sheen levels to enhance surface color, stamped pattern, or exposed aggregate.

Polyurethane Sealers

Known for their hard-wearing and non-yellowing protective layer, polyurethane sealers are suitable for both interior and exterior applications.

They offer different gloss levels and can also be tinted. High-traffic areas often utilize them for their excellent resistance to chemicals and abrasive materials.

Like Acrylic Sealers, these too come in both water and solvent-based formulations catering to many environments, including shopping centers.

Epoxy Sealers

These are ideal for interior applications where long-term surface protection is vital. There’s a range of epoxy sealers you can choose from; for example, some possess quick drying times necessary for shopping centers. Others provide superior strength fit for industrial and commercial areas like car parks. Their finish is glossy, but a more natural, matte finish can be achieved by adding a matting additive. Tinting options are also available.

Remember, irrespective of the type, the film-forming sealers provide a substantial level of protection. They also enhance the aesthetic appearance, making surfaces look livelier.

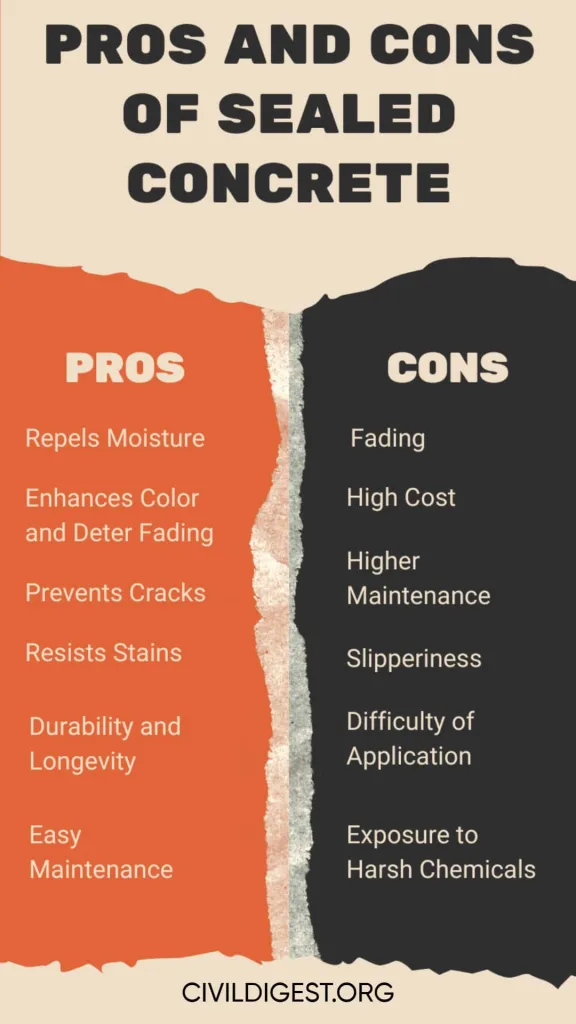

Advantages of Sealed Concrete

There are several advantages to having your concrete sealed. It offers protection, durability, and a visually appealing surface. Here are several reasons why sealed concrete is beneficial:

| Advantages | Description |

| Repels Moisture | Sealed Concrete doesn’t absorb water due to its non-porous surface. This not only prevents the growth of mold or moss, which can weaken the concrete, but also prevents damage to the concrete from constant moisture exposure. |

| Enhances Color and Deter Fading | Concrete sealing intensifies the color of the concrete, giving it a glossy and vibrant look. Plus, the seal prohibits the color from fading, maintaining its original, vibrant look for an extended period. |

| Prevents Cracks | The sealant closes off small pores and holes in the concrete which helps minimize cracking, preventing problems like frost heave on your paths. |

| Resists Stains | Sealed concrete is resistant to staining from the likes of oil and grease, ensuring any spillages can be wiped away without causing permanent damage. This makes it effective for places like the driveway, patio, garage, and pool deck. |

| Durability and Longevity | Sealing dramatically extends the lifespan of concrete. An unsealed driveway lasts for less than 20 years, but with regular sealing, it can last over 30 years, proving to be a cost-effective option compared to total driveway reconstruction. |

| Easy Maintenance | With the seal off, your concrete requires less intensive care. How frequently you reseal depends on the product used and weather conditions, and consulting an expert concrete sealing contractor can provide guidance on maintenance best practices. |

Disadvantages of Sealed Concrete

While sealed concrete offers numerous benefits, there are also some drawbacks to consider. Being aware of these cons will help you make an informed decision. Here are the main disadvantages associated with sealed concrete:

| Disadvantages | Description |

| Fading | Some concrete sealers contain harsh chemicals that can pose a health risk if inhaled or exposed to the skin. There are now safer alternatives in the market. |

| Cost | Sealing a concrete surface involves costs, including the cost of the sealant itself and possibly installation fees if you hire professionals for the job. |

| Maintenance | Sealed concrete demands more regular cleaning than raw concrete, adding to its maintenance needs. |

| Slipperiness | Certain sealants can cause the concrete surface to become slippery, increasing the risk of accidents, especially in wet conditions. Consider sealants with polymer grit additives that offer some traction. |

| Difficulty of Application | Applying a sealant can be time-consuming and tricky, particularly when dealing with large concrete surfaces. |

| Exposure to Harsh Chemicals | Some concrete sealers contain harsh chemicals which can pose a health risk if inhaled or exposed to the skin. There are now safer alternatives in the market. |

| Frequent Reapplication | Over time, due to regular use and weather conditions, the sealed surface may fade. To maintain the gloss and protection, reapplication every 2-5 years is often needed. |

| Potentially Harmful | Certain sealers contain Volatile Organic Compounds (VOCs), which affect air quality and can be harmful to the environment. |

| Not Applicable on Fresh Concrete | Applying sealer to newly poured concrete isn’t recommended. You might need to wait a month or so for the concrete to dry out completely before sealing your driveway. |

Selecting the Right Concrete Sealer

Choosing the correct concrete sealer is pivotal to achieving the best results. The choice depends on various factors, including the concrete’s use, its age, and your aesthetic preferences. Here are some tips to guide your selection:

- Aesthetic Appeal: If your goal is to enhance the glossy finish of the concrete, consider using a film-forming sealer.

- Natural Finish: For a more natural finish, opt for a penetrating or impregnating sealer.

- Stamped Concrete: Acrylic sealers, either solvent or water-based, are ideal for stamped concrete. They prevent reaction with UV rays, yellowing of the surface, and allow moisture to escape. These sealers are also economically friendly.

- Outdoor Sealing: Solvent-based acrylic sealers penetrate more deeply than their water-based counterparts and are suitable for outdoor use.

- Driveway Sealers: The objective is the defining factor for choosing driveway sealers. If safety is your primary concern, consider a penetrating sealer, as it doesn’t make the surface slippery. For aesthetics, topical sealers come in varying gloss levels.

- Concrete Surface Condition: The type of sealer varies depending on whether the concrete surface is new, old, or previously sealed. Dedicated sealers for specific conditions are available in the market.

- Harmful VOCs: Some sealers release Volatile Organic Compounds (VOCs) into the atmosphere when they dry. Select your sealer based on the standard VOC limits set by your country.

- Environmentally Friendly Option: Water-based sealers are less harsh and have the least VOC amount. Most are environmentally friendly and comply with the LEED principle.

Ensuring you select the correct concrete sealer can drastically improve the quality, longevity, and visual appeal of your concrete surfaces, ultimately enhancing your property’s overall visual appeal and value.

How to Apply Sealer to Concrete

Applying sealer to your concrete surface might seem intimidating, but with the right tools and steps, it can be a manageable DIY project. Here’s a step-by-step guide on how to correctly apply a sealer to your concrete:

Tools and Materials:

Tools

- Asphalt Brush: For sweeping the surface.

- Paint Sprayer: For quickly applying sealers over large areas.

- Paint Roller: Ideal for application on smaller areas or the second coat.

- Putty Knife: To fill in cracks and remove old sealant.

- Shop Vacuum: To clean up water and debris.

Materials

- Chemical Stripper: Used to remove the existing sealer.

- Concrete Repair: Fills in cracks and pits on the surface.

- Concrete Sealer: Protective layer applied to concrete.

- Degreaser: Helps remove oil and grease stains.

Steps:

1. Prepare the Surface

- Step 1: Clean the Surface: Clean the entire concrete surface thoroughly, removing any dust or debris.

- Step 2: Clean Deeply: Use your chosen cleaner to remove hard stains and residues such as paint, grease, or oil. Follow the manufacturer’s instructions for applying the cleaner.

- Step 3: Mop and Dry: Mop with floor cleaner and water. Use a shop vacuum to clean up the remaining water and let the surface dry for 24 hours.

- Step 4: Fix Cracks: Fill in any cracks or pits on the surface using a concrete repair product and smooth it out with a putty knife. Allow it to dry as per the manufacturer’s instructions.

2. Remove Old Sealer

- Step 1: Check for Old Sealer: Identify if there’s an existing sealer on your concrete. Pour a cup of water onto the concrete – if the water beads up, a sealer has been applied before. Use a chemical stripper to remove the old sealer. Ensure you wear protective clothing as specified by the stripper manufacturer.

- Step 2: Remove the Old Sealer: Apply the stripper evenly with a 1-inch nap roller or paint sprayer. Let it sit for the recommended time.

- Step 3: Scrape the Surface: Scrape off the sludge formed by the stripper. Make sure to dispose of it in an environment-friendly way.

- Step 4: Clean and Dry: Clean the surface with trisodium phosphate (TSP) and water then vacuum up the remaining water. Let it dry for at least 24 hours.

3. Apply New Sealer

- Step 1: Apply the First Layer: Apply the first coat of the sealer. If you’re covering a large area, a sprayer can make the process more convenient. Wait at least two hours before applying the second coat.

- Step 2: Apply the Second Layer: Apply the second coat at right angles to the first coat for consistent coverage.

- Step 3: Let it Dry: Let the sealer dry completely. This can take up to three days. Avoid stepping on or driving over the newly sealed surface until it’s entirely dry.

By following these steps, you should have a well-sealed concrete surface that not only looks good but extends the life of your concrete.

Conclusion

In conclusion, sealed concrete is a beneficial and attractive flooring solution that offers protection and enhances the beauty of concrete surfaces. Its advantages, from moisture resistance to durability, generally outweigh the few disadvantages. Choosing the right sealer for your needs and ensuring proper application is vital for the best results.