Having spent years in the construction field, I’ve seen firsthand the transformative power of crushed concrete. It’s more than just a cost-effective alternative to natural aggregates—it’s a game-changer in sustainable construction.

In this comprehensive guide, I’ll share insights from my own experience on what crushed concrete is, why it’s often a better choice than gravel, and how to accurately calculate the amount you’ll need for your next project. Plus, I’ll provide a crushed concrete calculator to make your life even easier. So, let’s get started

Table of Contents

What is crushed concrete?

Crushed concrete is essentially recycled concrete aggregate (RCA). It’s created from old concrete structures like buildings, roads, and runways that have been crushed into smaller pieces. It’s a sustainable option because it reuses waste materials.

The basic components of crushed concrete are:

Concrete: Mostly made of cement, water, and aggregates like sand or gravel.

Metal: Tiny bits of rebar or mesh for added stability.

Real-world Use Case

If you tearing down a small garage. Instead of letting the concrete waste end up in a landfill, it’s crushed and reused. It can serve as a base layer for a new driveway or as aggregate for new concrete.

The difference between gravel and crushed concrete

| Features | Gravel | Crushed Concrete |

| Material | Natural Stones | Recycled Concrete |

| Cost | More expensive | Cost-effective |

| Environmental Impact | High | Low |

| Texture | Rounded edges | Jagged edges |

Key Takeaways

- Gravel is natural; crushed concrete is recycled.

- Crushed concrete is generally more affordable.

- Crushed concrete is more eco-friendly.

Why use crushed concrete?

Sustainability: Using recycled materials lowers the demand for new natural resources.

Cost-Efficiency: It’s cheaper than using new aggregate or gravel.

Versatility: Great for driveways, pathways, and as a base layer for other projects.

In a project where you need a stable base, like laying down asphalt for a new road, crushed concrete is a stellar option.

What are the advantages of crushed concrete

Affordable: Often less expensive than gravel.

Eco-Friendly: Reduces landfill waste and lowers carbon footprint.

Durable: Its composition makes it resilient, and perfect for heavy-duty tasks.

Real-world Example

A research Conference done by Solid Waste Management in Asia and South East Island held in Japan shows that In a municipal construction project, switching to crushed concrete for the base layer saved 20% of the material cost without compromising quality. Over time, this translates to huge savings and reduced environmental impact.

What are the disadvantages of crushed concrete

Quality Variation: Because it’s recycled, quality can differ.

Limited Applications: Not suitable for all types of construction due to its texture and makeup.

Metal Traces: Sometimes contain tiny metal pieces, which might not be ideal for all uses.

Expert Advice

Always check the source and quality of crushed concrete before incorporating it into high-stakes projects like building foundations.

Types of Crushed Concrete

Different types are suited for specific applications, whether you’re laying a new driveway or stabilizing soil. Understanding these types can save you time and money, ensuring you choose the right material for your project. This section breaks down the various types of crushed concrete, including Type 1, Type 2, and Type 3, detailing their sizes and best use cases.

What is Type 1 crushed concrete?

Type 1 crushed concrete is one of the most commonly used sub-bases in construction and civil engineering projects. It’s typically composed of recycled concrete from buildings, roads, or other structures.

Common Uses

- Road construction

- Driveway bases

- Parking lots

Real-world Example

If you’re developing a new parking lot. Type 1 crushed concrete could be an ideal choice for your sub-base due to its ability to distribute the weight of vehicles evenly.

What size is Type 1 crushed concrete?

Type 1 crushed concrete is generally available in sizes ranging from 40mm down to dust. The more significant chunks help with weight distribution, while the dust aids in compaction.

| Size Range (mm) | Percentage Composition |

| 40-35 | 15% |

| 35-30 | 20% |

| 30-20 | 30% |

| 20-Dust | 35% |

Expert Advice

For projects like driveways or roads, go for Type 1 material with a well-graded size distribution. This ensures optimal compaction and strength.

What is Type 2 crushed concrete?

Type 2 crushed concrete is less commonly used than Type 1. It’s generally coarser and is used for specific engineering needs. It’s not typically suitable for use as a sub-base for residential applications.

Common Uses

- Road embankments

- Soil stabilization

Real-world Example

For instance, in a project that involves building a road on unstable soil, Type 2 crushed concrete can help stabilize the soil effectively.

What is Type 3 crushed concrete?

Type 3 crushed concrete is more finely crushed than Types 1 and 2. It often contains smaller particles and is used for specialized engineering tasks.

Common Uses

- Decorative features

- Drainage systems

- Pipe bedding

Real-world Example

If you’re managing a drainage project for a residential area. Type 3 crushed concrete is an excellent option for the drainage layer due to its finer size, which allows for better water flow.

Calculating Crushed Concrete Needs

When it comes to construction or renovation, you can’t ignore the materials. One vital material is crushed concrete. It’s not only cost-effective but also sustainable. Let’s dive deep into how to calculate the amount of crushed concrete you’ll need for your project.

How do you calculate crushed concrete?

Calculating crushed concrete starts with understanding the area you want to cover. Whether it’s for a patio or a road, the process typically involves using specific formulas to get your answers. Here’s how you can calculate it manually or you can use the online crushed concrete calculator tool below to calculate.

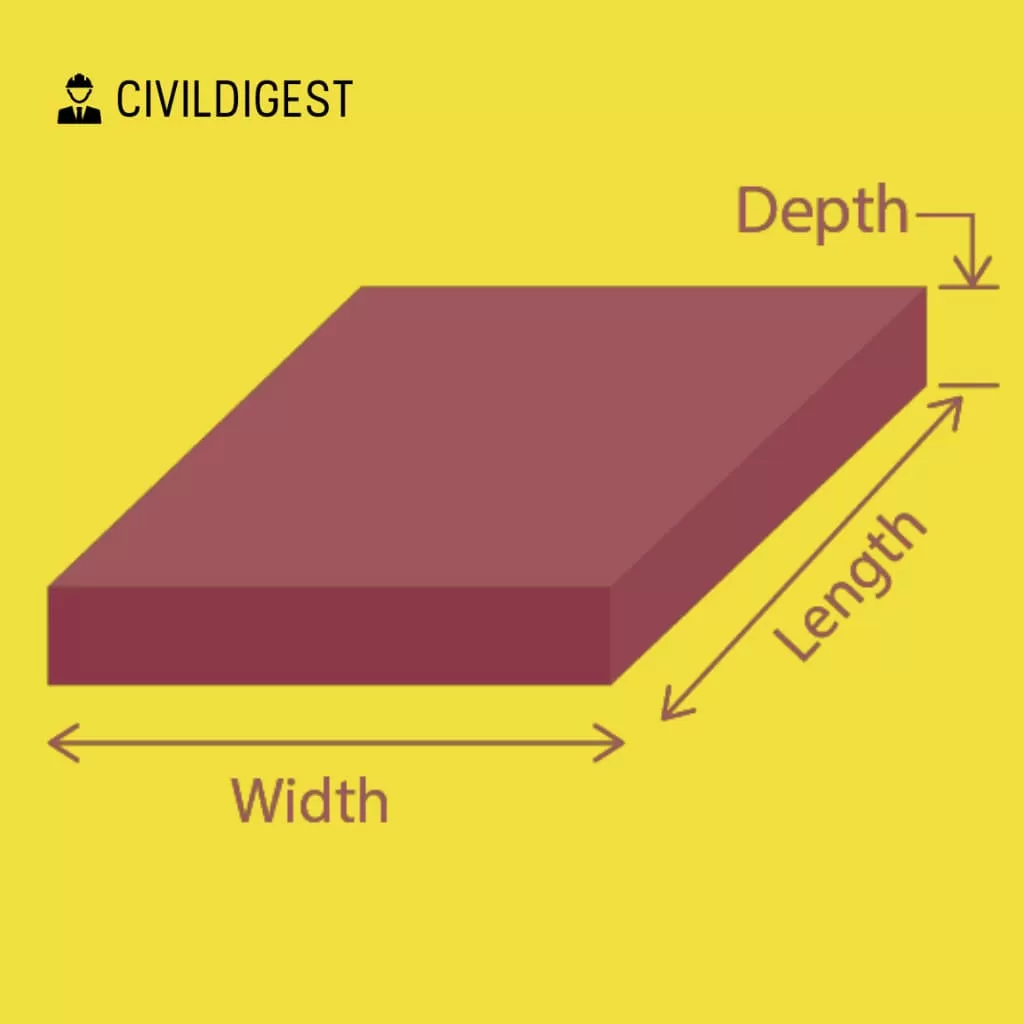

For square or rectangular areas:

S=(L×W×D)/27

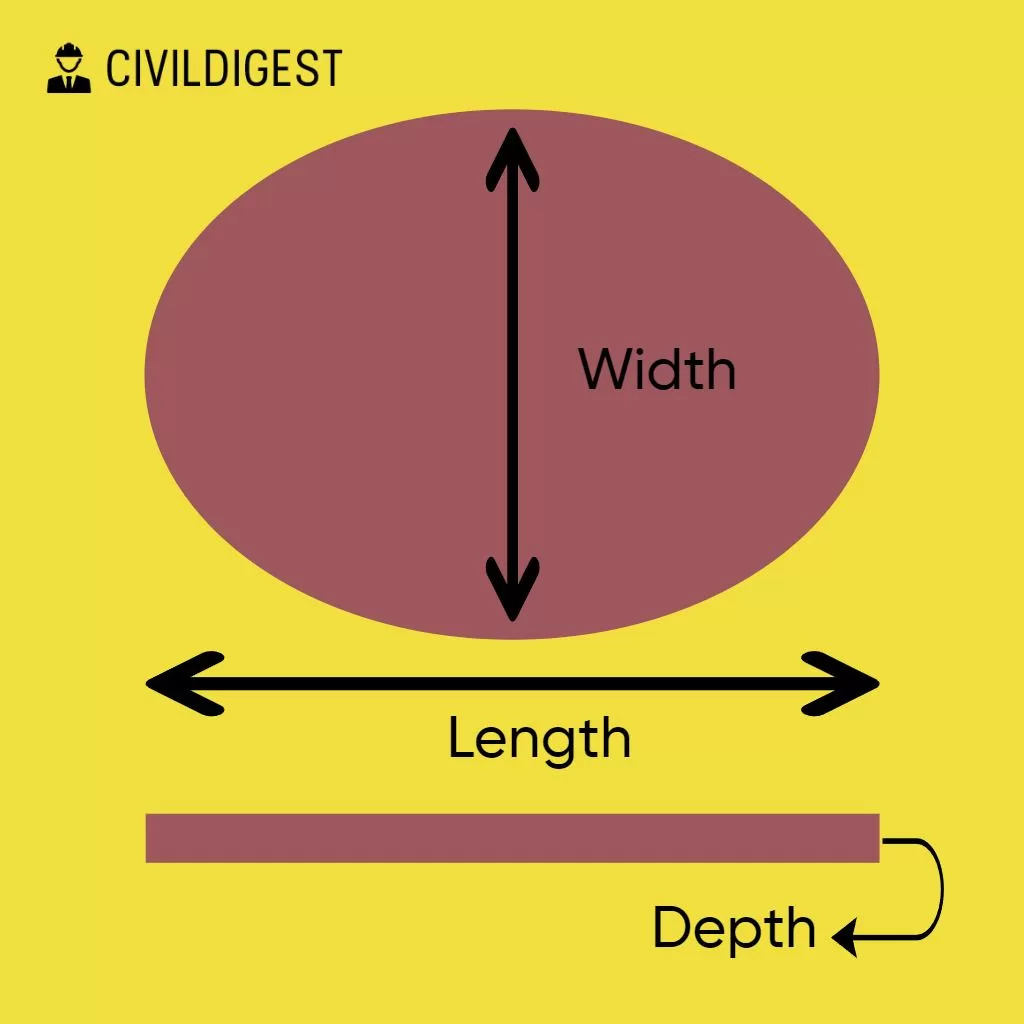

And for circular or elliptical surfaces:

S=(π× (L/2) × (W/2) ×D)/27

S – The required amount of crushed stones in cubic yards.

L – Length in feet where you want to lay out the crush.

W – Width in feet of the same surface for laying out the crush.

D – The depth in feet for the area you want to fill with the crush.

27 – Conversion factor from cubic feet to cubic yards.

Calculation for square or rectangular surfaces

Suppose we have a rectangular area that is 12 feet long (L), 9 feet wide (W), and we want to fill it with crushed stone to a depth (D) of 4 inches. First, we need to convert the depth from inches to feet, so 4 inches = 0.33 feet.

Using the formula S=(L×W×D)/27, we plug in our numbers:

S = (12 × 9 × 0.33) / 27 = 1.32 cubic yards.

Now, let’s include the 10% waste factor:

S(T) = S + (S / 10) = 1.32 + (1.32 / 10) = 1.45 cubic yards.

So, we would need approximately 1.45 cubic yards of crushed stone for this area.

Calculation for circular or elliptical surfaces

Now, let’s consider a circular area with a diameter (L) of 8 feet, and we want to fill it with crushed stone to a depth (D) of 4 inches (0.33 feet). For a circle, the width (W) is the same as the length (L).

The formula for a circular or elliptical surface is S=(π × L/2 × W/2 × D)/27.

Plugging in our numbers, we get:

S = (3.1416 × 8/2 × 8/2 × 0.33) / 27 = 0.61 cubic yards.

Now, let’s include the 10% waste factor:

S(T) = S + (S / 10) = 0.61 + (0.61 / 10) = 0.67 cubic yards.

So, for a circular area with these dimensions, we would need approximately 0.67 cubic yards of crushed stone.

Remember, these calculations include a 10% waste factor to account for any errors or spillage during the project.

Related: How Many Bags of Concrete in a Yard?

How do you calculate tons of crushed stone?

Conversion Factor

To convert the volume in cubic feet to tons, you’ll need a conversion factor. Generally, crushed stone is around 1.25 tons per cubic yard. Therefore, to convert cubic feet to tons:

Weight in tons=(Volume in cubic feet×(1.25/27))

Volume in cubic feet: Calculated from the previous section.

1.25: Average weight of crushed stone per cubic yard.

27: Number of cubic feet in a cubic yard.

Example Calculation

Continuing from our previous example where the volume needed is 5 cubic feet.

Weight in tons=(5×1.25/27)=0.23 tons

You’ll need approximately 0.23 tons of crushed stone for the pathway.

How many tons is 1 yd of crushed concrete?

Crushed concrete usually weighs about 2,040 kilograms per cubic yard, approximately 2.25 tons.

Here’s a simple calculation:

Weight in tons=1yd×2.25tons/yd=2.25tons

So, a cubic yard of crushed concrete would weigh around 2.25 tons.

What is the maximum dry density of crushed concrete?

The maximum dry density (MDD) of crushed concrete varies based on composition, but it’s generally around 120-145 pounds per cubic foot (pcf). In simpler terms, that’s how much a small container of dried and crushed concrete would weigh if you packed it as much as possible. The MDD is crucial for engineering tasks because it informs you how compact a material is.

Properties of Crushed Concrete

Knowing the properties of crushed concrete is important for your construction project. It informs you about the material’s limitations and possibilities, ensuring you’re making educated decisions. This section will cover essential aspects like density, weight, compaction rate, permeability, and chemical composition.

What is the density of crushed concrete?

The density of crushed concrete can vary based on the origin and composition of the concrete being crushed. Generally, it ranges from approximately 2,100 kg/m³ to 2,500 kg/m³ (131 lbs/ft³ to 156 lbs/ft³).

Calculation

Density is calculated by dividing mass by volume. This is commonly done through a core sample test on the crushed concrete. In the field, you would extract a known volume and weigh it to find the density. The formula for density is:

Density=Mass/Volume

Real-World Example

Suppose you’re involved in laying the foundation for a new building. The site requires 300 m³ of crushed concrete. Knowing the density helps you estimate the mass required.

If we consider a density of 2,400 kg/m³ for illustration:

Total Mass Required=Density×Volume

Total Mass Required=2,400kg/m³×300m³=720,000kg=720Tons

This calculation provides you with an accurate estimate of how much-crushed concrete you would need for your project.

How heavy is crushed concrete?

Knowing the weight of crushed concrete allows you to accurately plan logistics and assess the load-bearing capabilities of the sub-base. Generally, the weight of crushed concrete will depend on its density and the volume you are working with.

Calculation

The weight of crushed concrete is found by multiplying its density by the volume. Here’s how you do it:

Weight=Density×Volume

Real-World Example

For instance, if you need to fill a space measuring 5m³ and the density of your crushed concrete is 2,400 kg/m³, then:

Weight=2,400kg/m³×5m³=12,000kg

This would mean you’d require 12 tons of crushed concrete for your project.

How much does a cubic metre of crushed concrete weigh?

A cubic metre is a unit of volume, and its corresponding weight in crushed concrete depends on its density. For example, if the density is 2,400 kg/m³:

Calculation

Weight of 1 Cubic Metre=2,400kg/m³×1m³=2,400kg

In this example, one cubic metre of crushed concrete would weigh 2.4 tons.

How much does 1 ton of crushed stone weigh?

While crushed concrete and crushed stone are similar in many ways, their densities can differ. Crushed stone typically has a density ranging from 2,600 to 2,800 kg/m³.

Table: Density Range of Crushed Stone

| Type of Stone | Density (kg/m³) |

| Limestone | 2,610 |

| Granite | 2,675 |

| Basalt | 2,900 |

Real-World Example

If you’re using limestone with a density of 2,610 kg/m³, one ton would occupy:

Volume=1,000kg/2,610 kg/m³≈0.383m³

In this example, one ton of limestone would roughly equal 0.383 cubic meters.

Knowing the weight of the materials you’re working with is essential for project planning and execution. It influences the choice of machinery, cost estimation, and safety measures, ensuring that your project goes off without a hitch.

Crushed Concrete in Construction

Crushed concrete is a recycled material with a range of applications in the construction industry. Not only is it cost-effective, but it’s also environmentally friendly and offers solid structural support. In this section, we’ll cover how to use crushed concrete effectively and how it’s made.

Making crushed concrete

Creating crushed concrete involves recycling concrete waste from construction sites or demolition projects. Here’s how it’s done:

Steps to Produce Crushed Concrete:

- Collection: Gather the concrete waste from construction sites.

- Sorting: Remove any contaminants like rebar, wood, or plastic.

- Breaking: Use industrial crushers to break down large pieces of concrete.

- Screening: Sort the crushed material by size.

- Quality Control: Samples are tested for quality and strength.

- Storage: Store the finished product in a dry place until it’s ready for use.

Types of Crushers Used:

- Jaw Crusher

- Impact Crusher

- Cone Crusher

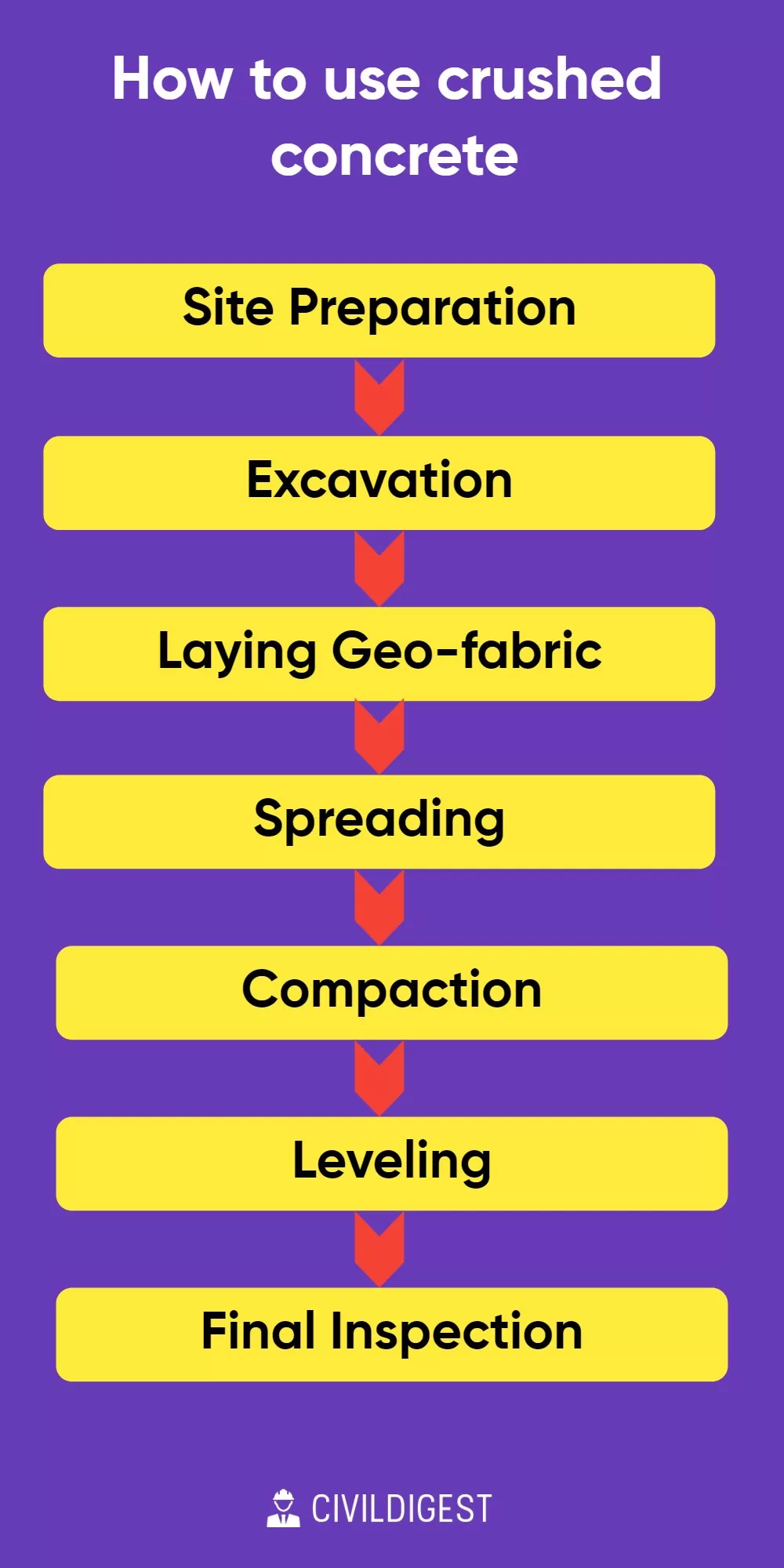

How to use crushed concrete

Using crushed concrete is similar to using other aggregate materials, but there are some specific steps and considerations to keep in mind.

Step-by-step Guide to Using Crushed Concrete:

- Site Preparation: Remove any debris or obstacles from the area where you intend to lay the crushed concrete.

- Excavation: Dig the area to the depth required for your project.

- Laying Geo-fabric: This prevents soil from mixing with the crushed concrete.

- Spreading: Distribute the crushed concrete evenly using construction machinery like a bulldozer.

- Compaction: Use a vibratory roller or plate compactor to compact the material.

- Leveling: Make sure the surface is level for the next layer, such as asphalt or concrete slabs.

- Final Inspection: Conduct a quality check to ensure that the crushed concrete is adequately compacted and leveled.

Recommended Equipment:

- Excavator

- Bulldozer

- Vibratory roller

- Plate compactor

Can crushed concrete be used as aggregate?

Certainly, crushed concrete can be used as aggregate in various construction projects. It’s commonly utilized in road construction, drainage systems, and as a base for building foundations.

Benefits of Using Crushed Concrete as Aggregate:

- Cost-Effective: It is generally cheaper than virgin aggregate.

- Eco-Friendly: Recycling concrete reduces waste in landfills.

- Structurally Sound: Offers good compaction and load-bearing capabilities.

| Benefit | Explanation |

| Cost-Effective | Cheaper than virgin aggregate |

| Eco-Friendly | Reduces landfill waste |

| Structurally Sound | Offers good compaction and load-bearing |

Can you mix cement with crushed rock?

Yes, you can mix cement with crushed rock to produce concrete. The crushed rock acts as the aggregate, enhancing the concrete’s structural integrity.

Ingredients for Mixing Cement and Crushed Rock:

- Cement

- Crushed rock

- Water

- Optional: Admixtures for added strength or workability

What is the best crushed stone for concrete?

Choosing the right type of crushed stone is crucial for the concrete’s durability and strength. Typically, limestone, basalt, and granite are the best options.

Criteria for Selecting Crushed Stone:

- Hardness: Should withstand compressive forces.

- Texture: Rough-textured stones offer better bonding.

- Size: 3/4-inch to 1-inch diameter is most common.

| Criteria | Ideal Feature |

| Hardness | High compressive strength |

| Texture | Rough |

| Size | 3/4-inch to 1-inch diameter |

How thick should crushed concrete be?

The thickness of the crushed concrete layer depends on its application. For driveway bases, a 4-inch thickness is generally suitable. For more substantial constructions like roads or large foundations, a thickness of up to 8 inches may be required.

Calculations for Thickness:

For a driveway, you’d need about:

- 4 inches of crushed concrete

- Covering 300 square feet

- The density of crushed concrete: ~2,410 kg/m³

Volume = 300 sq ft × (4/12) ft = 100 cubic feet = 100 cubic feet × 0.0283168 m³/cubic foot = 2.83 m³

Weight = 2.83 m³ × 2,410 kg/m³ = 6,824.3 kg = 6.8 tons (approx)

So, you’d need approximately 6.8 tons of crushed concrete for a 4-inch thick, 300-square-foot area.

By considering these aspects, you can make more informed decisions when working with concrete in various construction scenarios.

Compaction and Permeability

Understanding compaction and permeability is essential in the field of civil engineering. These properties determine how well-crushed concrete will perform as a sub-base material.

What is the compaction rate of crushed concrete?

The compaction rate tells you how much a material can be compressed. For crushed concrete, the compaction rate is generally between 90% to 95%.

Calculation

To find the compaction rate, use the formula:

Compaction Rate=( Maximum Dry Density/Dry Density)×100

Real-World Example

Suppose your project needs a layer of crushed concrete with a volume of 500 m³. The maximum dry density is 2,400 kg/m³, and you achieve a dry density of 2,280 kg/m³.

Compaction Rate=( 2,400/2,280 )×100≈95

Achieving a 95% compaction rate means you’re hitting the mark for most construction applications.

How permeable is crushed concrete?

Permeability measures how well water passes through a material. Crushed concrete generally has a permeability rate ranging from 1 to 5 cm/hr.

- Particle size

- Porosity

- Saturation level

Real-World Example

In a roadway project, if drainage is a concern, you’d opt for crushed concrete with higher permeability. For a rainwater runoff rate of 2 cm/hr, using crushed concrete with a permeability of 5 cm/hr ensures efficient drainage.

What is the chemical composition of Crushed Concrete

Crushed concrete is primarily made up of concrete aggregate. However, the chemical composition can vary depending on the original concrete mix and any additives.

Table: Typical Chemical Composition

| Constituent | Percentage (%) |

| Silicon Dioxide | 50-60 |

| Calcium Oxide | 20-25 |

| Aluminum Oxide | 5-10 |

| Other Oxides | 1-10 |

Understanding the chemical makeup helps in applications where chemical resistance or reactivity matters. For instance, certain chemicals used in industrial sites may not be compatible with standard crushed concrete.

Conclusion

In conclusion, crushed concrete is not just an affordable choice but also an environmentally friendly and versatile material. From its multiple types to its unique properties, it offers a range of options for your construction or garden projects.

Understanding how to calculate your needs—whether in tons or cubic yards—can help you streamline costs and avoid unnecessary expenses. As someone who has spent years in the field, I can vouch for the utility and durability of crushed concrete, especially when compared to traditional gravel.

Don’t forget to make use of the crushed concrete calculator for a more accurate estimate. If you want a material that provides a blend of cost-efficiency, sustainability, and versatility, crushed concrete should be at the top of your list.