In this article, you will learn how to properly mix and lay concrete.

Table of Contents

Concrete Materials and handling

When cement is mixed with water, alkali is released, which can be harmful.

When mixing concrete, precautions must be taken to avoid dry cement entering the eyes, mouth, and nose.

Suitable protection must be taken to prevent skin contact with wet cement or concrete.

If cement or concrete enters the eye, immediate and thorough washing with clean water is imperative, followed by medical treatment without delay.

Wet concrete must be washed off the skin immediately.

Materials must be checked with manufacturer’s certificates and specifications.

If you are not satisfied, refer them to the supplier immediately.

Check, in particular, that the cement is the correct type, that the protection against rain and dampness is effective, and that the bags, if bagged, are free of damage.

Cement in bags

Cement should be stored in a dry, weather-proof, enclosed shed or building with a dry floor.

Store it on a timber platform if the floor is concrete.

Stack bags closely together, but no more than eight bags high, away from walls.

Stack bags so that consignments can be delivered in the order they were received.

Handling and site storage

- Cement in bulk

Store it in a proper cement silo, making certain that:

The silo mechanism is cleaned on a regular basis in accordance with the manufacturer’s installation instructions.

Unless the mechanisms are cleaned on a regular basis, they become clogged and the cement feed becomes irregular.

- Aggregates

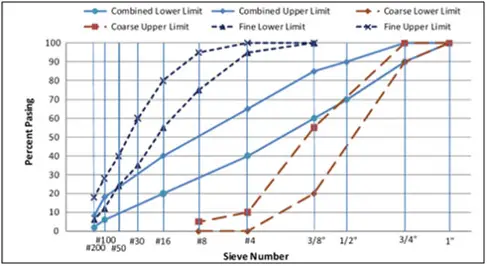

Coarse and fine aggregates are clean, conform to the correct single or graded sizes, and meet the following requirements:

Handling does not result in particle segregation of various sizes.

The various sizes and types are kept strictly apart.

They are stored on a hard, clean base that allows for free drainage.

They are not contaminated by leaves, garbage, dirt, or other harmful substances.

In hot weather with long periods of sunshine, the stockpiles are periodically covered or sprayed with clean water to reduce the temperature of the aggregates.

- Water

If a mains supply of water is not available, seek instructions.

Before using, protect the water from contamination.

- Other materials

All materials, such as admixtures, pigments, and so on, should be stored so that they can be easily identified and do not become mixed up or contaminated.

Mixing

- Batching by mass

Make certain that the proper materials are chosen.

Measure the aggregates and cement by weight, and the water by volume or mass.

Allow for water contained in the aggregates when measuring the mass to be batched.

Keep track of the quantity of each material batch.

1 kg is the mass of 1 L of water. As a general rule, the water content of aggregates should be 6% to 7% by mass for sand, 1% to 2% for coarse aggregate, and 4% to 5% for all-in aggregate.

Moisture should be measured if greater precision is required.

- Characteristic strength of concrete

The characteristic strength of concrete is the strength of concrete specimens cast and tested in accordance with a specific code of practice and cured for 28 days; 95% of tested cubes should not have a value less than this value.

- Concrete Compressive Strength

The characteristic compressive strength of 150 mm cubes tested at 28 days is used to calculate concrete compressive strength. The characteristic strength of concrete is defined as the strength below which no more than 5% of the test results are expected to fall below the grade strength.

- Mix Design example for Grade 30 Concrete

Absolute volume cement = 350kg / (3.15 x 1000) = 0.1111 m3

Water per cubic meter at a w/c ratio of 0.6 = 350*0.6/1000 = 0.21 m3

Assume 6% air voids for 1 m3 = 0.06 m3

Volume of Coarse and Fine Aggregate = 1.0-0.111-0.21-0.06 = 0.6189 m3

35% sand = 0.35 x 0.6189 = 0.216615 m3,

In mass = 0.216615 x 2.65 x 1000 = 574 kg

65% coarse aggregate =0.65 x 0.6189 = 0.402285 m3

In mass = 0.402285 x 2.65 x 1000 = 1066 kg

Total weight = 350+210+574+1066 = 2200 kg

- Unless otherwise specified, do not mix different types of cement together.

- Some cements are incompatible with one another, and mixing them can have serious consequences for the strength of the resulting concrete.

Admixtures

- Unless otherwise specified or instructed, do not use any admixture.

- Admixtures must be measured, prepared, and incorporated into the concrete mix in strict accordance with the manufacturer’s site-work instructions.

Mixing time

Mixing time for rotating-type mixers is typically 1.5 to 2 minutes and 30 to 45 seconds for pan-type mixers.

Mixers and batching plants must be well maintained, and weighing mechanisms must be checked and calibrated on a regular basis.