Quality control and assurance are critical components of construction project management.

Table of Contents

Introduction to Quality Assurance and Quality Control

A contractor has a better chance of acquiring business if the quality of his work is excellent, in addition to efficiency.

Quality management in a construction firm is not a separate activity but is entwined with all of the company’s operational and managerial activities.

As a result, the contributions of quality control, quality assurance, and total quality management to construction quality must be considered.

The definition of quality terms

Entity

A product, process, activity, machine, service, system, department, corporation, institution, or organization is considered an entity.

An entity has features resulting from its stated or implied demands.

The sum of these particular needs-oriented traits constitutes an entity’s quality.

Quality

Hence, the term “quality” can be described as “meeting the requirements of the customer specified by characteristics that define the entity.”

Control

Being “in control” or having something “under control” means not allowing things to go out of hand.

Quality control

Quality control can be defined as “a set of activities or techniques whose purpose is to ensure that all quality requirements are being met”.

It is mostly made up of the actions and plans that are used to meet and keep a product, process, or service’s quality.

It entails monitoring, but it also entails identifying and removing the sources of quality problems so that the customer’s requirements are consistently met.

Concerns about Quality Control

The primary goal of quality control is to detect defects.

Inspection and statistical quality control procedures (such as sampling) are the most common ways to make sure that the work done and the materials used are within the limits set.

Some of these limits are left to the inspector’s discretion, which can be problematic.

The major objectives of quality control

To guarantee that the rendered job fulfills the specifications.

To decrease consumer or client complaints.

To increase the validity and reliability of products or services produced.

To boost customer or client confidence.

To cut production costs.

What is the key feature of all quality control systems?

Inspection is the key component of all quality control systems.

In the case of construction, inspection is divided into two types: quantifiable (e.g., line, levels, verticality, and measurements) and interpretable (e.g., cleanliness, fit, tolerances, and visual inspections). Some inspections are exact and quantifiable, such as pressure tests on pipework and strength tests on materials like concrete.

The evolution of quality assurance from quality control

Traditional quality control is the practical application of techniques to guarantee work quality is satisfactory.

The main issue with this method is that it is performed after the task has been completed.

To address this issue, quality assurance was devised.

What is Quality Assurance?

Quality Assurance (QA) is a set of actions or processes used to demonstrate that an entity meets all quality requirements.

This has evolved to ensure that specifications are constantly met through planned and regular efforts (including documentation).

The concepts of quality assurance are “fit for purpose” and “right first time,” and the frame of reference for quality assurance is the International Quality Standard (ISO) 9000 series of standards.

The end goal of quality assurance is to provide the client with the required quality of work without requiring client check-ins throughout the process.

A client who purchases a car, for instance, does not stress to see the car’s assembly.

This purpose is met by documenting what activities are conducted and how they are carried out, by self-checking that each process has been completed correctly, and by documenting that information.

Quality assurance is important because it stresses “doing it right the first time” so that the contractor doesn’t have to pay for things that aren’t necessary.

Most construction contracts will have a clause that says contractors have to fix any work that doesn’t meet the project’s quality standards.

Since this remedial action work is performed at the contractor’s cost, it provides a powerful incentive for the contractor to adopt a quality assurance approach.

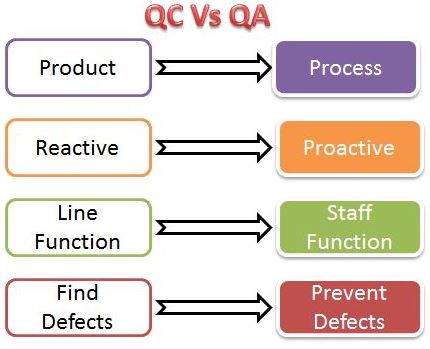

In contrast to quality control, which focuses on fault discovery after the item has been created or constructed, quality assurance (QA) stresses defect prevention.

Quality assurance focuses on managerial techniques and procedural procedures that ensure quality is incorporated into the production system.

Quality assurance (QA) is a comprehensive term for preventing quality problems, which will include: a good-quality management system that requires an assessment of its sufficiency, an audit of the system’s operation, and a review of the system altogether.