In this article, you will learn how to properly mix and place concrete.

For a better understanding, read part 3 here.

Table of Contents

Deep Lifts

Concrete placement in deep lifts is more cost-effective.

Not only does the technique save time, but it also reduces the number of horizontal joints.

However, the mix must be designed to minimize segregation and bleeding.

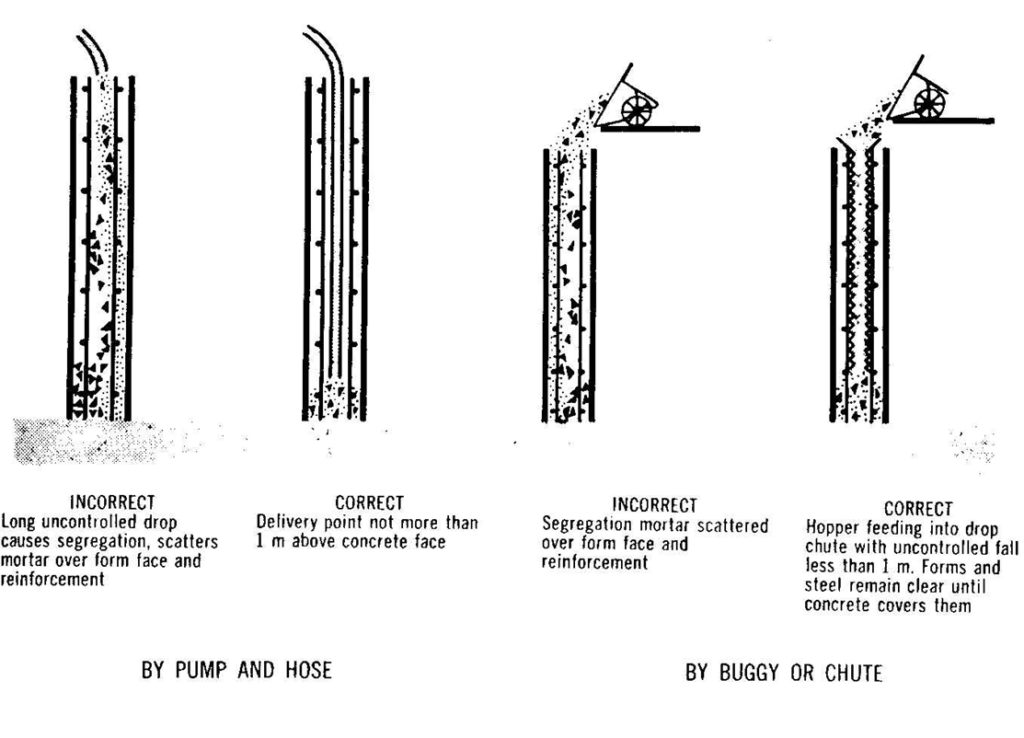

The concrete should be introduced into the form via trunking, as this reduces impact damage to forms and reinforcement and allows for even layering of concrete.

For high lift use chutes or trunking to direct the concrete into position.

Transporting Concrete

Move the concrete as quickly as possible from the mixer to its final location, or as close to it as possible, so that it can be laid down before it becomes too hard to move or pack.

Transport the concrete in a way that will not cause the ingredients to separate.

Maintain the cleanliness of the containers.

If the concrete is transported in dumpers or barrows that bump up and down over rough terrain, the stone particles will sink to the bottom.

As much as possible, avoid rough tracks.

Transporting methods of concrete

Where vertical movement is predominant, the crane is the most commonly used method of handling concrete.

A crane is frequently required on the job site to handle formwork and reinforcement, and its additional use in transporting concrete to the point of placement may be both convenient and cost-effective.

Pumping Concrete

Concrete transport and placement by pump is becoming increasingly popular.

It is very fast and efficient, with little concrete waste.

Not all concrete will pump, and minor differences in the concrete mix can render an otherwise pumpable mix completely unpumpable.

As a result, the design mix must be given special consideration.

The location of the pumps on the property should be given some thought.

If the concrete is to be supplied by ready-mixed concrete trucks, two trucks should ideally be able to discharge into the pump’s hopper.

In this manner, one can finish discharging concrete while the other begins to discharge without a break in continuity.

Concrete work below ground level

Check the faces of excavations for stability and accuracy before pouring strip footings, bases, and slabs against them.

If they are not, follow instructions.

Place the concrete in such a way that the sides of the hole do not move.

If the concrete face is to be formed against the excavation, the cover to the reinforcement should be at least 75 mm.

Displacement when pouring concrete

Ensure no displacement or damage to damp proof membranes, reinforcement, formwork, or embedded fittings takes place whilst placing.

Concrete compaction

Compact the concrete, making certain:

a) It solidifies into a uniform, void-free mass;

b) it is densely packed around the reinforcement

c) it fully fills all formwork or excavation;

d) There is no separation of ingredients;

e) it is mixed in with previous batches

f) no damage to partially hardened concrete adjacent;

g) the required finish will be achieved;

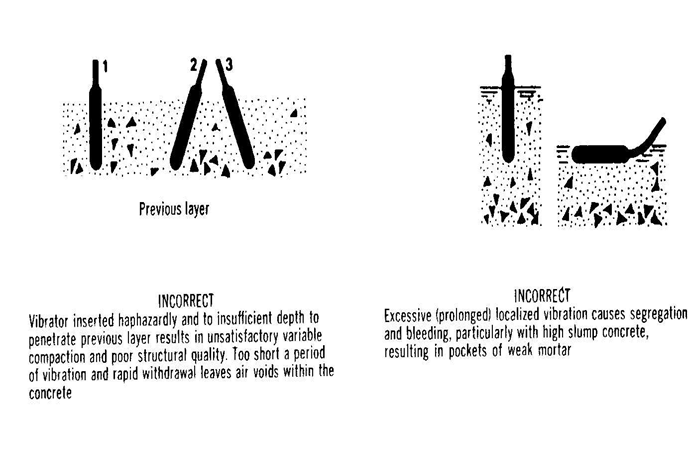

h) Mechanical vibrators, if used, are of the appropriate type for the situation and are operated by qualified personnel.

Concrete must be compacted to contain the least amount of unwanted air if it is to achieve its maximum strength.

With a wet workable mix, this is simple, but the excess water in this type of concrete contributes to its weakness.

The strongest and most durable concrete is as dry as it can be compacted using the available means.

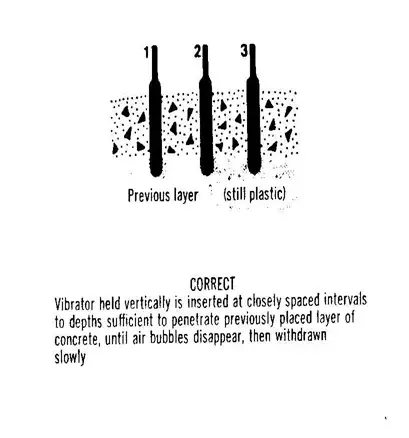

The internal vibrator, also known as a poker, is the most common type of vibrator.

It should be inserted vertically into the concrete, held in place until air bubbles no longer rise to the surface, and then gradually withdrawn.

This should be repeated at 0.5 meter intervals.

The concrete should be laid in layers no thicker than 600 mm.

And the vibrator descended at least 100 mm into the layer below.

Inadequate compaction can have a significant impact on the quality of the concrete.

When air bubbles no longer rise to the surface of the concrete near the poker vibrator, the concrete is fully compacted.

Vibrating deep sections

For wall columns, beams, and so on,

Place and compact concrete in layers, ensuring that each layer covers the entire length and width of the section.

Place subsequent layers without delay and compactionally merge them with the layer below.