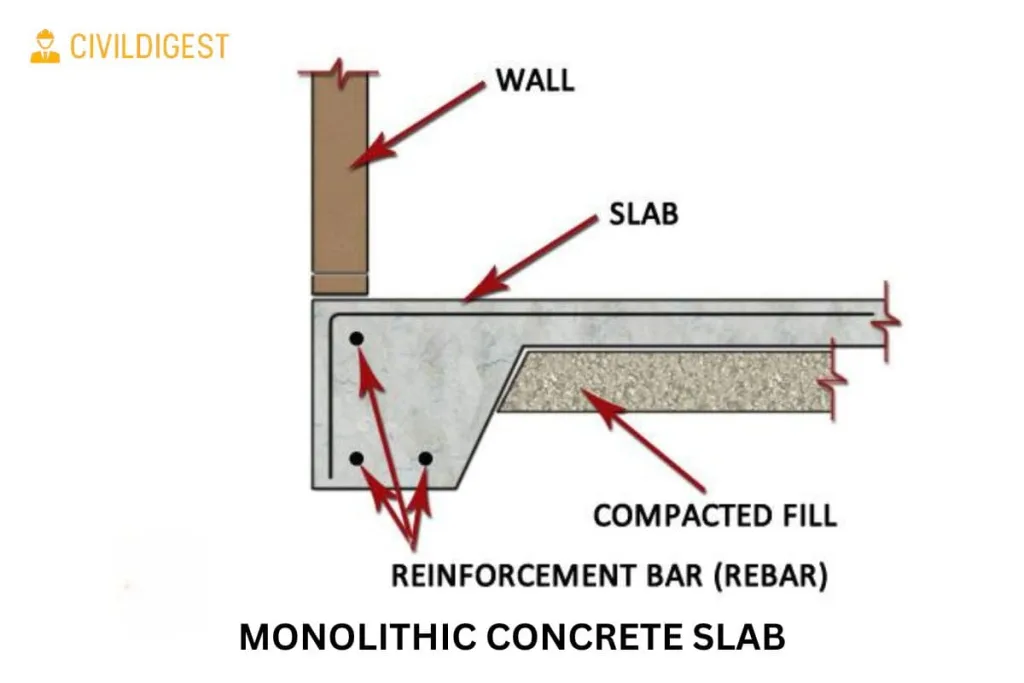

A monolithic concrete slab is poured as a singular element, maintaining uniform thickness, typically between 6-8 inches. Termed as “slab on grade”, it’s a foundation created in one application.

Due to affordability and durability, it’s a favored foundation in the USA. Moreover, they’re ideal for climates without extreme winter freezes or scorching summer heat.

Table of Contents

Advantages of a Monolithic Slab Foundation

- Quick Construction: Monolithic slabs are faster to lay due to their single-pour nature.

- Cost-Effective: Reduced labor time means decreased construction costs.

- Strength: With the correct installation of anchor bolts and reinforcements, these foundations are robust.

- Low Maintenance: Regular inspections are the main upkeep, ensuring the foundation remains crack-free.

- Energy Efficiency: No space between the home and the ground leads to minimized energy waste. Air doesn’t circulate under the subfloor, leading to better insulation.

- Durability: These slabs stand the test of time, proving a reliable base for constructions.

- Faster Drying Time: They dry quicker than other cement foundation types, speeding up construction timelines.

Note: Always ensure level ground for optimal monolithic slab benefits.

Here is research on the design of monolithic concrete ground floors for your additional knowledge.

Disadvantages of a Monolithic Slab Foundation

- Flood Risk: Homes with this foundation are raised about 6 inches, increasing the flood danger.

- Expensive Repairs: Repairing a cracked monolithic slab is costly due to limited accessibility.

- Potential Reduced Resale Value: Some buyers might see it as a less appealing option.

- Cracking Issues: Not suitable for uneven grounds. Uncompacted or filled grounds can lead to cracks.

- Incompatibility with Flood Zones: In flood-prone areas, monolithic slabs might lead to structural damages.

- Structural Concerns: Cracks in the foundation can lead to wall damage.

Note: Always consider the type of soil and flood risks before opting for a monolithic slab foundation.

Construction of a Monolithic Concrete

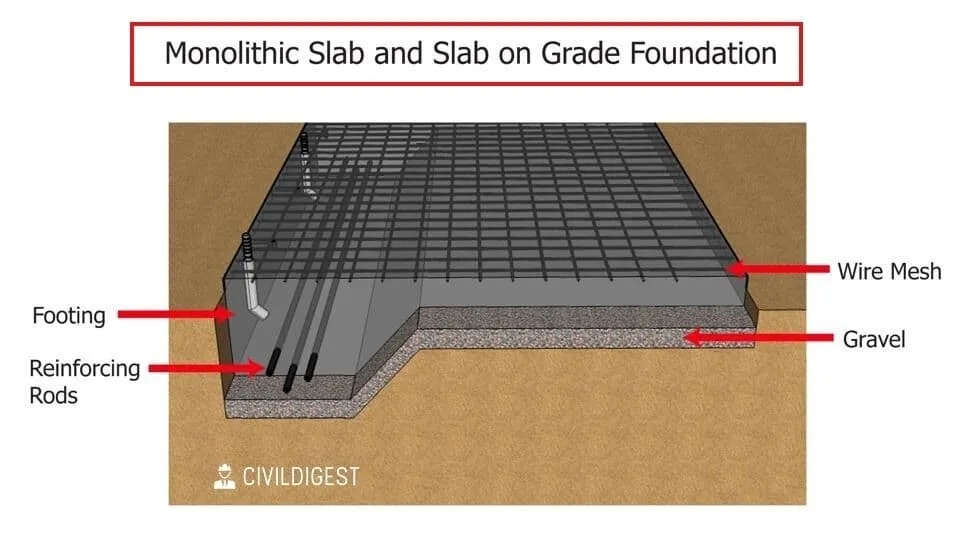

Monolithic concrete construction involves casting concrete as a single, unified component, incorporating the slab and the footings simultaneously. This efficient method is characterized by its one-pour technique, making it distinct from traditional stepwise construction. Proper site preparation, drainage considerations, and strategic reinforcement placement are essential for optimal results.

Site Preparation for Monolithic Slab Construction

- Soil Conditions: It’s vital to use compacted soil devoid of organic matter. Once the topsoil is removed, the undisturbed soil below is typically suitable.

- Water Flow Management: Proper drainage is essential. Plan for water redirection to prevent undercutting of the slab.

- Perimeter Trenches: A trench around the slab’s perimeter offers a thickened edge. Depending on the locale, trenches can be 1 ft deep and wide in warmer areas or up to 2 ft deep in colder regions with frost concerns.

- Gravel Layer: Use compacted gravel, 3-1/2 to 4 inches or more, both under the slab and within the trenches. Typically, well-draining gravel with aggregates ranging from 3/8 to 3/4 inch is chosen.

- Reinforcement: As per local codes, reinforcements might include 6-inch by 6-inch woven wire mesh, held by rebar chairs to position it centrally in the finished slab. #4 rebar is commonly used to reinforce the thickened edge, with continuous bars positioned low and high in the trench.

Conclusion

Monolithic concrete slabs present a unified and efficient approach to foundation construction. Characterized by their singular pour and consistent thickness, they offer multiple advantages, including speed of construction, cost-effectiveness, robustness, and energy efficiency. Despite their merits, it’s essential to be aware of potential challenges such as flood risks, repair costs, and compatibility with specific terrains.