A concrete slab is a common structural element of modern buildings, comprising horizontal flat surfaces made of cast concrete. Concrete slabs provide stability, distribute loads, and often act as a vital layer separating spaces.

As we delve deeper into this article, we will explore the various types of concrete slabs, their unique characteristics, and their specific applications in the vast world of civil engineering and construction.

Table of Contents

Different Types of Concrete Slabs

In this section, we will discuss various types of concrete slabs, each with its distinct features and applications. Each of these slabs serves specific purposes in construction and offers unique advantages. Dive into each subsection to gain a comprehensive understanding of their characteristics and uses.

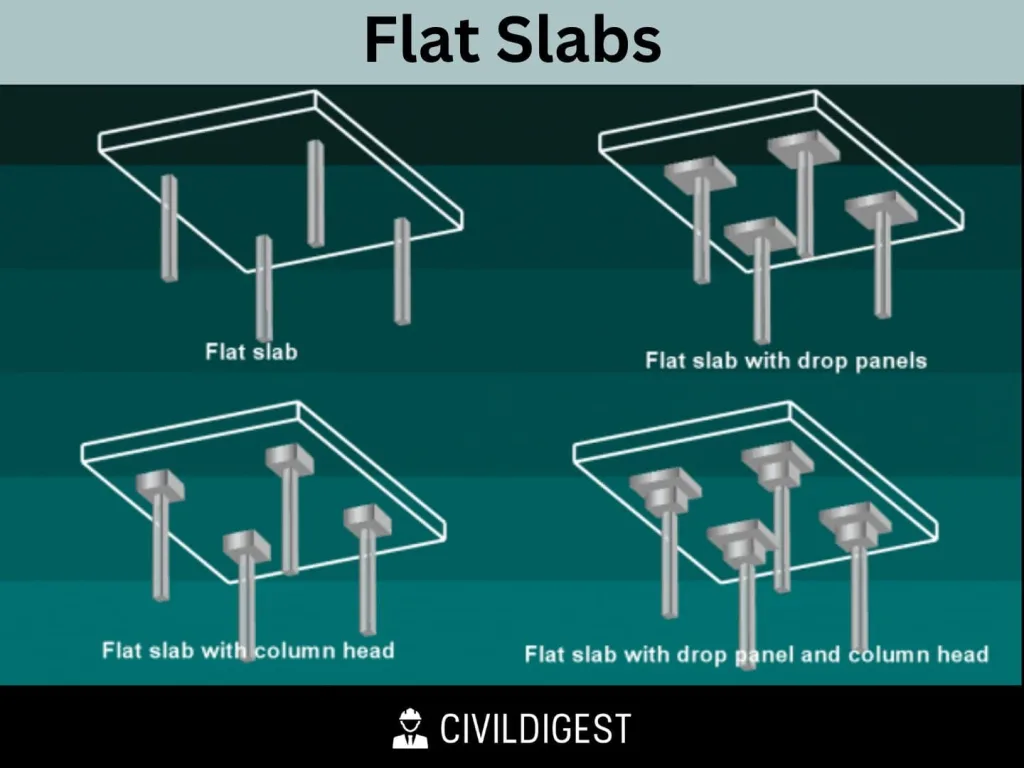

Flat Slabs

A flat slab is a reinforced concrete slab that’s supported directly on columns, distinguishing itself by the absence of beams.

Flat slabs find their application in diverse settings like commercial structures, residential complexes, parking facilities, and in scenarios where a seamless ceiling look is the design goal.

Flat slabs are favored because they streamline the construction process by removing the need for beams, resulting in an open and aesthetically appealing ceiling space.

Opting for flat slab construction comes with several advantages, including efficient construction timelines, enhanced design adaptability, potential cost savings due to fewer materials and labor, and a modern, uninterrupted ceiling appearance.

The span of a flat slab typically lies between 6 to 9 meters, although this can vary based on specific design parameters and anticipated load conditions.

In many standard residential structures, a flat slab will have a thickness ranging from 12 to 14 centimeters, but this might adjust depending on structural demands and loads.

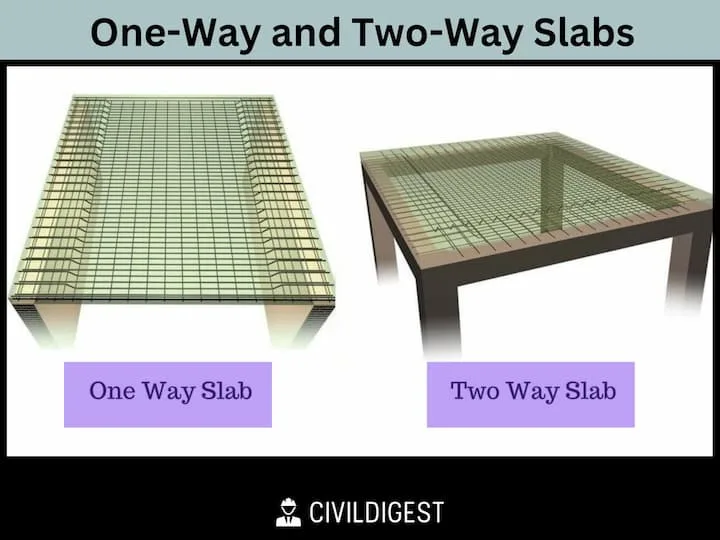

Conventional Slabs (One-Way and Two-Way Slabs)

A conventional slab, often used as a foundational element in construction, is a horizontal structural component designed to bear loads.

Made from materials like concrete, these slabs are predominantly categorized into one-way and two-way slabs based on their load distribution.

Conventional slabs are fundamental in creating floors and ceilings in buildings. They offer a flat surface upon which other building elements, such as walls or partitions, can be erected. Additionally, they help distribute and transfer loads from the structure to the supporting columns and beams.

- One-Way Slab: This type of slab spans in one direction, usually supported on two opposite sides by beams or walls. It bends predominantly in one direction, thus, distributing the loads along one direction only. Commonly found in narrow rooms or hallways.

- Two-Way Slab: In contrast, a two-way slab spans in both directions, supported by columns without any major beams. It effectively distributes loads in both its length and width. Typically used in wider rooms or areas where a more uniform load distribution is needed.

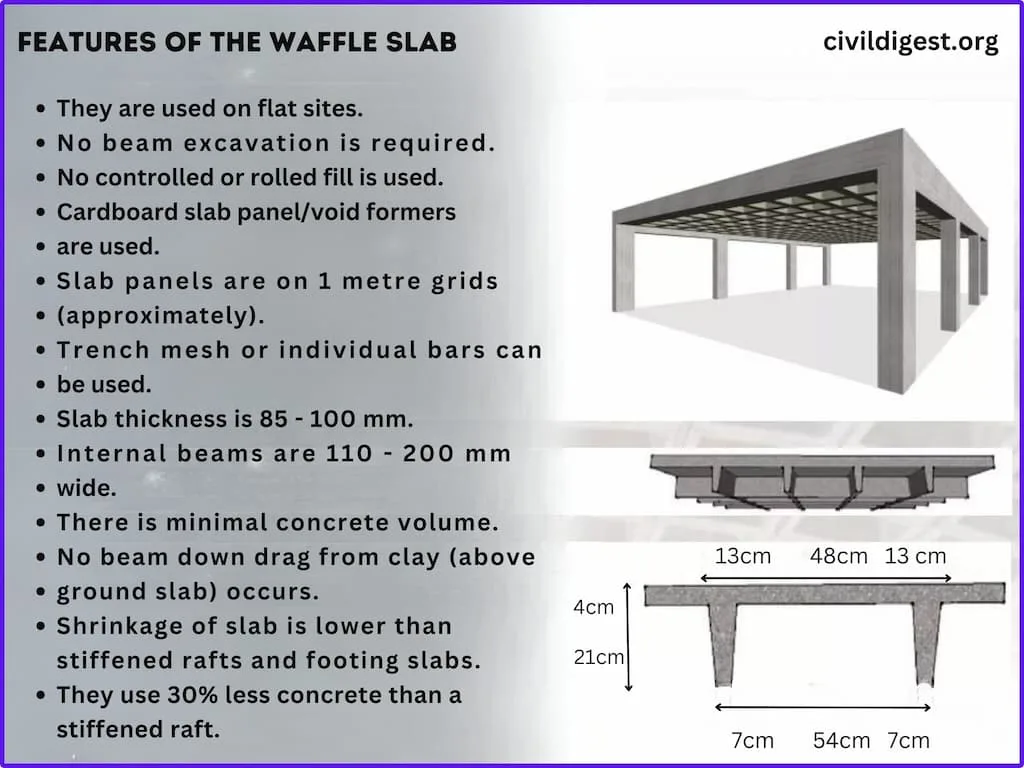

Waffle Slabs

A waffle slab, named for its grid-like appearance reminiscent of a waffle, is designed to be efficient in spanning in two directions.

It’s typically used in large areas where the slab needs to cover a vast space without the requirement for many columns, like large auditoriums or commercial spaces. The voids in the waffle slab reduce the weight of the slab, making it efficient for spanning over larger areas.

Waffle slabs come with several benefits:

- Material Efficiency: The voided design uses less concrete, reducing material costs.

- Span Capability: Suitable for larger spans with fewer supports.

- Weight Reduction: The design inherently reduces the self-weight of the slab.

- Aesthetics: Unique appearance can serve as a design feature in some architectural contexts.

Waffle slabs are distinguished by:

- A grid-like system of ribs, creating voids between them.

- Typically a flat top surface, with the “waffle” design evident on the underside.

- Often use of prefabricated molds or formwork for casting.

- Ability to span in two directions, making them two-way slabs.

One primary limitation of waffle slabs is the complexity in construction. The requirement for specialized formwork and the intricacy of placing reinforcement can lead to increased labor costs and construction time compared to conventional slabs.

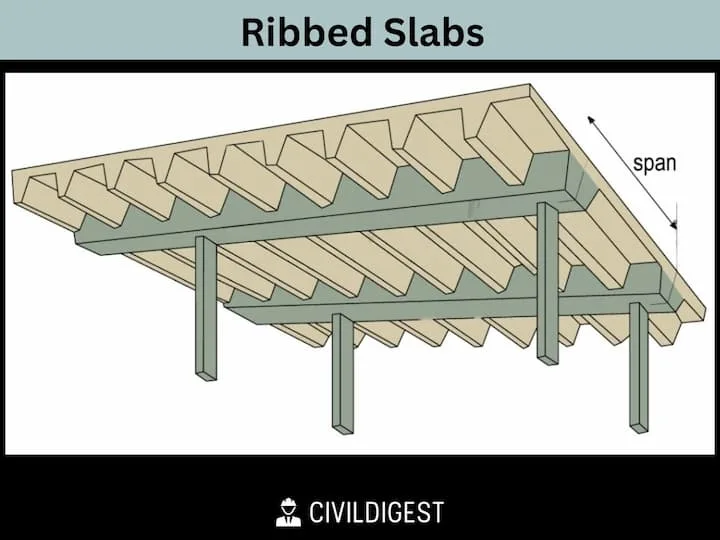

Ribbed Slabs

Ribbed slabs are a type of reinforced concrete slab characterized by a series of parallel ribs or joists underneath the main slab portion. These ribs provide added structural strength while using less concrete, thanks to the voids between the ribs.

Ribbed slabs are primarily employed in structures requiring large spans with lighter slab weights, such as commercial buildings, multi-story car parks, and residential complexes. Their design efficiently uses materials while still maintaining structural integrity.

The overall thickness of ribbed slabs, including the top slab portion and the ribs, typically ranges between 100 mm to 500 mm.

The span capability of ribbed slabs largely depends on factors like rib spacing, slab thickness, and the kind of loads they will support. Generally, ribbed slabs can comfortably span distances up to 9 meters or more.

Ribbed slabs offer several distinct advantages:

- Material Efficiency: Reduced concrete volume due to the voids, leading to cost savings.

- Lightweight: The design minimizes the self-weight of the slab.

- Large Span Capability: Suitable for spanning larger distances without the need for many supporting columns.

- Thermal Comfort: The voids can assist in insulation, offering better thermal comfort in some scenarios.

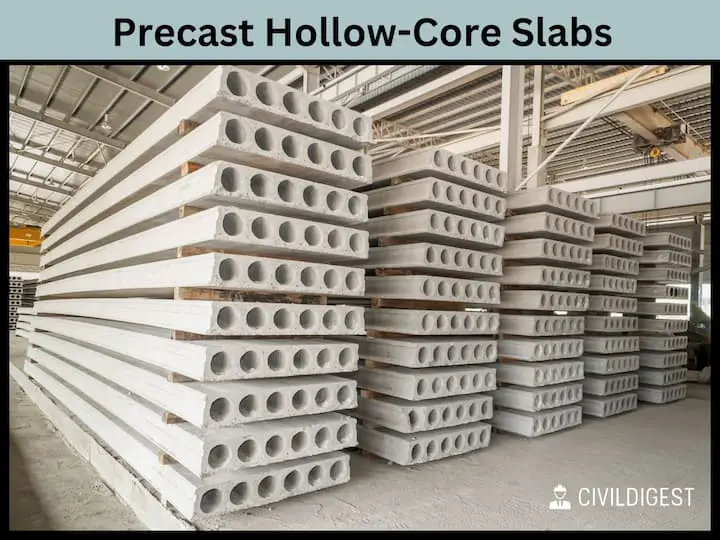

Hollow-Core Slabs

A hollow core slab is a precast, pre-stressed concrete slab with longitudinal voids or “cores” running through its length. These voids make the slab lighter than a solid concrete slab of the same thickness.

Hollow core slabs are utilized for their efficiency in spanning long distances without the need for many intermediate supports. Their reduced weight minimizes the loads imposed on the rest of the structure, making them ideal for multi-story buildings and reducing the need for additional foundational strength.

The production of hollow core slabs involves extruding or slip-forming wet concrete through a machine with special shaping features. As the concrete is pushed out, it wraps around long steel tendons, which are subsequently tensioned. Once the concrete achieves the desired strength, the tension is released, inducing compression in the slab. The resulting product is a pre-stressed slab with hollow cores running its length.

Key characteristics of hollow core slabs include:

- Longitudinal voids or “cores” that reduce weight.

- Ability to span long distances with minimal support.

- Being pre-stressed, which improves load-bearing capacity.

- Speedy installation due to their precast nature.

- Typically manufactured in widths of 1.2 meters or wider, with varying thicknesses depending on the design requirements.

The advantages of using hollow core (or hollow block) slabs include:

- Weight Reduction: The cores significantly reduce the self-weight of the slab.

- Material Efficiency: Uses less concrete compared to a solid slab, leading to cost savings.

- Thermal and Sound Insulation: The hollow cores can offer improved insulation properties.

- Quick Installation: Being precast, they can be rapidly installed on-site.

- Flexibility: Can accommodate utilities within the cores, such as electrical or plumbing services.

Precast Slabs

A precast slab refers to a concrete slab that is manufactured in a controlled factory environment before being transported and installed at the construction site.

Unlike traditional concrete slabs that are cast in place on-site, precast slabs are produced off-site and brought to the location when needed.

The manufacturing process of precast slabs involves several steps:

- Mold Preparation: Reusable molds, shaped according to the slab’s specifications, are prepared.

- Mixing and Pouring: Concrete is mixed, ensuring a consistent and high-quality blend, and then poured into the molds.

- Curing: The poured concrete is allowed to set and gain strength in a controlled environment, ensuring uniform curing.

- Demolding and Storage: Once sufficiently cured, the slab is removed from the mold and stored until it’s ready for transport to the construction site.

- Transportation and Installation: Using cranes or other heavy machinery, the slab is placed in its final position at the construction site.

Several advantages are associated with the use of precast concrete slabs:

- Quality Control: Being manufactured in a controlled environment ensures consistent quality and strength.

- Speedy Construction: Since slabs are ready-made, construction timelines can be significantly shortened.

- Reduced On-Site Labor: The need for on-site formwork and curing is eliminated, leading to fewer workers on-site.

- Durability: Precast slabs often have enhanced durability due to controlled production conditions.

- Economic: In large projects, the repetitive use of molds and bulk production can lead to cost savings.

Post-Tensioned Slabs

A post-tensioned slab is a concrete slab in which steel tendons are tensioned after the concrete has reached a specific strength or after it has cured. This post-tensioning imparts a compressive force to the concrete, enhancing its capacity to bear tensile loads.

Post-tensioned slabs are employed primarily to overcome concrete’s natural weakness in tension. By inducing a compressive force using tensioned steel tendons, the slab’s tensile capacity is increased. This method is particularly beneficial for spanning large areas without the need for excessive supports or when designing slabs on expansive soils.

For post-tensioned (PT) slabs, high-strength concrete is typically used in conjunction with high-tensile steel tendons. The concrete mix is usually designed to achieve strengths of 3,000 psi (pounds per square inch) or higher, depending on the project’s requirements. This ensures that the slab can effectively counteract the forces applied during the tensioning process.

Utilizing post-tensioning in slabs offers several notable benefits:

- Efficient Material Use: Allows for thinner slabs and longer spans, reducing the amount of concrete and reinforcement required.

- Reduced Cracking: The compressive forces introduced by post-tensioning can minimize or even eliminate concrete cracking.

- Flexibility in Design: Architects and engineers have more freedom in designing building layouts, as PT slabs can span large areas without intermediate supports.

- Cost-Efficiency: Although the initial investment might be higher, savings from reduced material use and faster construction timelines can offset the costs.

- Durability: PT slabs, by resisting cracking, can provide longer service life and reduced maintenance costs.

Here is a step-by-step guide video for the post-tensioned slab procedure.

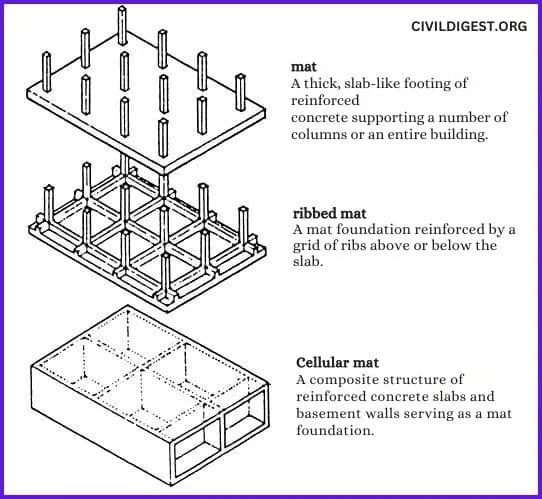

Mat or Raft Slabs

A raft or mat slab is a type of foundation system in which a thick concrete slab, reinforced with steel, is used to cover the entire area of a structure. It extends across the full footprint of a building, distributing loads from the superstructure evenly across the ground beneath.

Raft or mat slabs are employed in situations where other foundation types, like individual footings, might not be suitable. They are particularly beneficial in areas with:

- Poor soil conditions, where load distribution is critical.

- High water tables, making deep foundations problematic.

- Situations where basements are desired, with the raft slab forming the basement floor.

- Sites with expansive clays or soils prone to significant volume changes.

Opting for this foundation type presents several benefits:

- Uniform Load Distribution: The extensive footprint ensures that building loads are spread evenly across a larger soil area.

- Reduced Differential Settlement: By distributing loads uniformly, the chances of differential settlement are minimized.

- Suitability for Poor Soils: It’s an effective solution when building on compressible or expansive soils.

- Structural Integrity: The continuous slab provides a rigid base, enhancing the structure’s stability.

- Cost-Efficiency: In some scenarios, particularly with poor soils, raft or mat foundations can be more economical than deep foundation systems.

Composite Slabs

A composite slab combines two or more materials, typically concrete and steel decking, to maximize the beneficial properties of each. The steel deck provides tensile strength and acts as a formwork during the casting of the concrete. Once the concrete cures, the combination works together, leveraging the concrete’s compressive strength and the steel’s tensile capabilities.

Composite slabs bring forward several advantages:

- Efficiency in Construction: The steel decking acts as a formwork, eliminating the need for temporary formwork.

- Load-Bearing Capacity: The combination of concrete and steel enhances the slab’s load-bearing abilities.

- Speed of Construction: Quicker installation due to the integrated formwork and reduced curing times.

- Cost Savings: The efficient use of materials and reduced labor can lead to cost benefits.

- Ductility: The inclusion of steel provides ductility, enhancing the structure’s ability to withstand dynamic loads.

Composite slabs are predominantly used in multi-story buildings, especially commercial structures like office buildings, malls, and industrial facilities. Their speed of construction makes them particularly suited for large-scale projects where timelines are tight.

Conclusion

In modern construction, concrete slabs are essential. These slabs come in various types, each designed for specific structural needs. Flat slabs offer architectural freedom, while hollow-core and post-tensioned slabs provide efficiency and long span capabilities. Conventional slabs distribute loads in two directions, waffle slabs have a distinct grid-like design, and composite slabs combine strengths. Understanding these slabs is crucial for professionals, as the choice of slab impacts a project’s structural integrity and efficiency.

FAQs about concrete slabs

What type of slab is best suited for areas with poor soil conditions?

A raft or mat slab is ideal for areas with poor soil conditions as it distributes building loads evenly across a larger soil area.

How do hollow-core slabs reduce the overall weight of a structure?

Hollow-core slabs have longitudinal voids or “cores” running through their length, reducing the slab’s weight compared to a solid concrete slab of the same thickness.

Why are post tensioned slabs considered beneficial for large spans?

Post-tensioned slabs are pre-stressed to enhance their capacity to bear tensile loads, making them efficient for spanning large areas without excessive supports.