This article will bring you the procedure for mixing and placing concrete in detail.

For a better understanding, read part 6 here.

Table of Contents

Construction Joints

Concrete cannot be placed continuously in most cases.

Construction joints must thus be provided only where necessary.

Such joints can be a source of weakness.

They should be carefully located and formed, and their number should be kept to a minimum.

Joints should be vertical or horizontal wherever possible.

Vertical joints must be in a straight line with rigid stop ends in the formwork, designed to accommodate projecting reinforcement without temporary bending or displacement.

To prevent grout loss, foam plastic strips and adhesive tape are wrapped around the bars.

When the formwork is removed, the horizontal joints are level and show a straight line.

Before beginning any concreting, the position of construction joints should be determined.

Column joints are generally made as close to the beam haunching as possible.

Beam and slab joints should typically be made in the center or within the middle third of the span.

Preparing for next pour at a construction joint

Before placing new concrete against a construction joint, the joint surfaces should be thoroughly roughened and cleaned to remove all lost material and laitance.

Should not cause any disturbances to the coarse aggregate.

The joint surfaces should be wet, but there should be no free water on the joint surfaces or anywhere else where fresh concrete will be placed.

The following procedures should be followed when cleaning the concrete face of a construction joint to receive concrete:

2-6 hrs :Use a soft brush

6-24 hrs : water jet

24 -72 hrs : wire brush

Over 72 hrs : Scabbling

Movement Joints

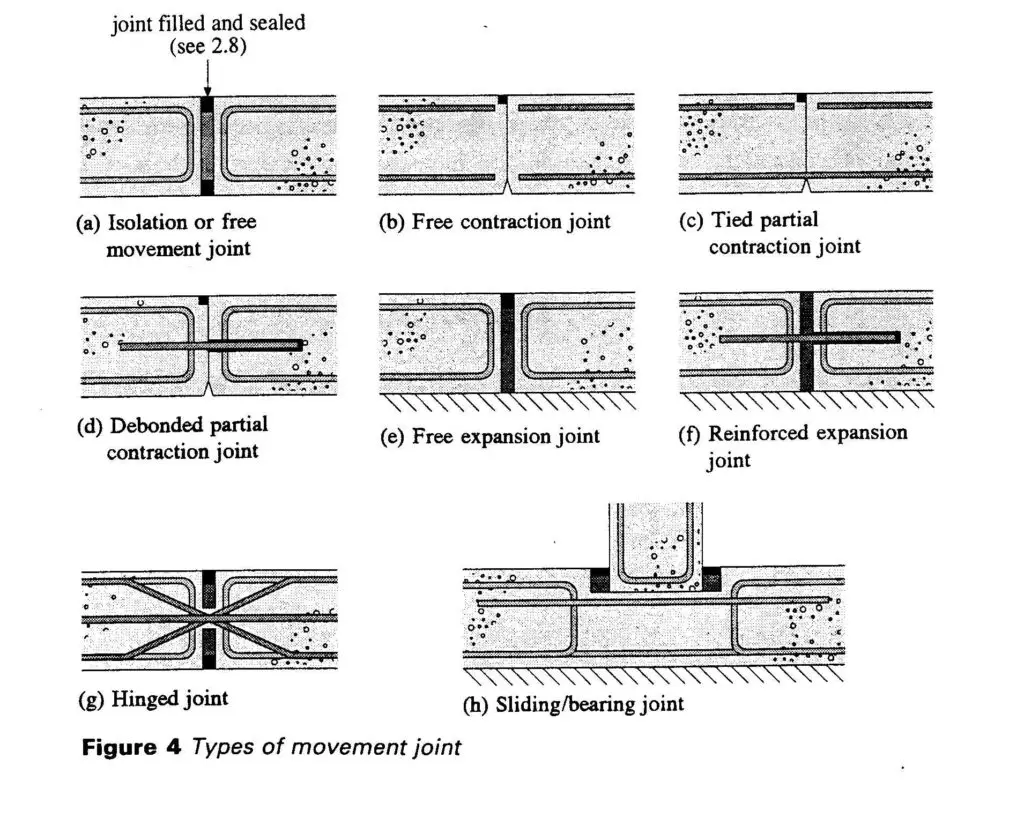

To allow movement, discontinuous joints, also known as movement joints, are used. This is usually done to protect the concrete structure and other building components from damage.

They can be completely discontinuous or free-movement joints, with complete freedom of translation and rotation.

They can also be partially discontinuous, allowing objects to move freely along or around some axes while limiting or stopping movement along others, transferring force along those axes.

Both types of joints may be required to perform additional functions, such as water exclusion above and below ground and in water-retaining structures.

Form joints only as directed, and:

a) Do not allow concrete to enter any gaps or voids in the formwork, as this will render the movement joints ineffective.

b) Do not allow concrete to impregnate or penetrate any compressible joint filler materials;

c) Do not pour concrete on both sides of the joint at the same time.

Joint fillers and Sealants

The chemical composition and intended usage of concrete joint sealants and joint fillers are dissimilar. Standard Specification for Elastomeric Joint Sealants (ASTM C 920) defines sealants as “cold-applied elastomeric single or multi-component materials used for sealing, caulking, or glazing operations on buildings, plazas, and decks for vehicular or pedestrian use, and construction types other than highway and airfield pavements and bridges.”

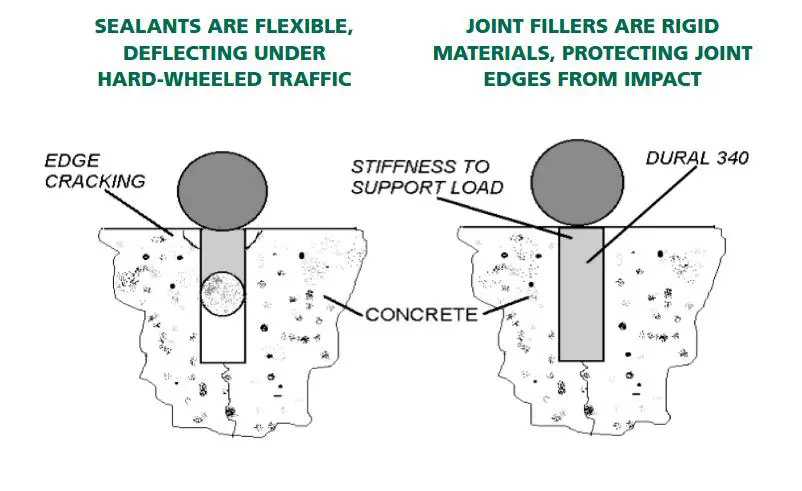

The basic function of a joint sealant is to keep out water, dirt, and debris. Sealants are often composed of polyurethane, silicone, or acrylic, and are soft and flexible. They are intended to expand and interact with the joint. Hard-wheeled vehicles, carts, and pallet jacks will cause a sealant-filled joint to deflect, leaving the junction’s edges vulnerable. This causes the edges to break and spall. Repairing spalled joints can be a costly undertaking. Repairing a joint is projected to cost four times as much as filling the joint with the right material in the first place.

Joints in industrial floors that are prone to heavy and/or hard-wheeled traffic should be filled with a semi-rigid joint filler; a sealant should only be used to fill isolation joints at walls or columns and under racks that are not subject to traffic. Epoxy and polyurea semi-rigid joint fillers restore the continuity of a concrete floor whose surface has been sliced into joints. Because they are composed of hard, relatively rigid materials, joint fillers prevent damage to joint edges caused by the impact of harsh wheels and high loads.

Moreover, due to their rigid structure, joint fillers cannot be stretched laterally. If joint fillers were made of flexible materials, they would deflect under load like sealants do, rendering them incapable of protecting the joint edge. Do not be deceived by the high percentage elongation or expansion value of a joint filler. While joints widen as a result of slab shrinkage, they do not lengthen. Since joint filler cannot expand as the joint widens, the only other option is for the filler to detach or split.